The use of SAFETRACK micro-trenching solutions has played a key role in the successful completion of a major fibre optic broadband installation project in Galway, Ireland.

The requirement was to run cables between connecting junction boxes, placed at 1km intervals, along busy roads that could only be closed for short periods of a few hours during the day. Micro-trenching works by cutting small (20mm wide and 150mm deep) trenches as compared to the 300mm width and 600mm depth, which is typically required with more traditional techniques. Micro-trenching enables much faster installation speeds with significantly reduced costs.

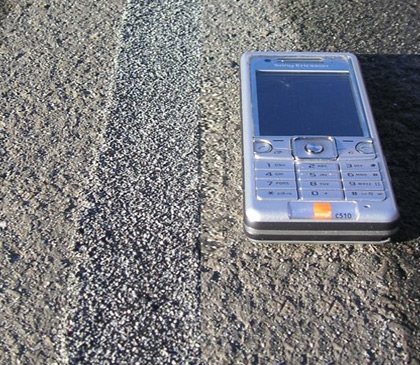

Reinstating the asphalt road surface

The success of this new technique, to cut the trench and lay the cables, was reliant on finding an infilling technique that would successfully reinstate the road surface to a safe, serviceable state quickly and efficiently. Galway City Council had strict performance criteria for the solution, which needed to offer strength, flexibility and water resistance that would ensure long lasting asphalt reinstatement.

A spokesman for the contractor said, “one of the key requirements for this project was a reinstatement process that would not compromise the road structure in any way. Standard reinstatement products would not give us the strength and flexibility required.”

Accelerating road repairs

Galway City Council selected SAFETRACK MTI from Stirling Lloyd (now GCP Applied Technologies). The contractor’s spokesman said, “They have a proven track record on the Shetland Islands micro-trenching project and the HAPAS certification we required.”

Based on unique ESSELAC technology, this cold applied product appealed to the client, since failures had occurred on previous projects in Ireland where hot bitumen-based products had damaged the fibre optic cables.

The SAFETRACK MTI completely fills the micro-trench without requiring compaction and seals it against water ingress. The free flowing SAFETRACK MTI easily penetrates a narrow trench, forming a strong bond to the cut asphalt faces.

The solution behaves like asphalt, helping to ensure a long service life. The speed and ease of application, together with fast cure, enabled the infill to be applied quickly. The contractor was able to excavate, lay the fibre optic cable and reinstate up to 250 linear metres a day, within very short road closures which is more than three times as fast as traditional techniques. In addition, due to the small footprint of the installation, the works were carried out with minimal road closure time.

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://ca.gcpat.com/fr-ca/about/project-profiles/safetrack-mti-rapid-micro-trench-reinstatement-0