Two examples of field test results depicting typical CLARENA® MC2000 field performance are shown below.

Field Test 1 Arizona (Urban Ready-Mix plant)

Nine 4 cubic yard batches of concrete were batched and tested. As detailed in Table 1, three chemically distinct Mid-Range Water Reducers (DARACEM® 55, MIRA® 95, CLARENA® MC2000) were tested in triplicate, with all plastic and hardened data represented by averages of the 3 tests. Mix design specifics included 456 pcy (271 kg/ m3)Type I/II cement, 124 pcy (74 kg/m3) Type F fly ash, 970 pcy (576 kg/m3) #1 coarse aggregate, 820 pcy (487 kg/m3) 3/8” coarse aggregate, 1320 pcy (783 kg/ m3) fine aggregate and 300 pcy (178 kg/m3) water.

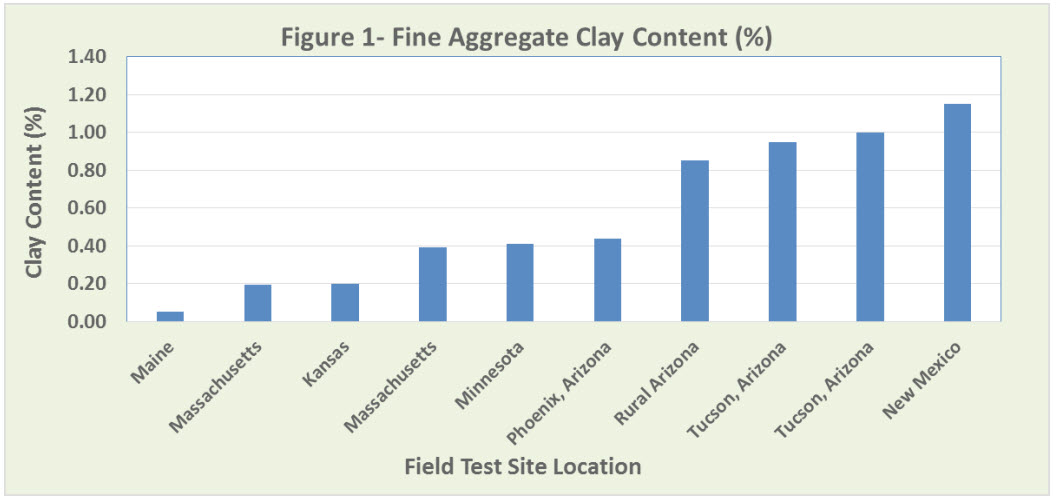

The fine aggregate sampled prior to field testing had MBV value of 1.00 mg/g and 0.44% clay, which is considered to be moderate, but relatively low for the SW region.

Field test results revealed MIRA® 95 and CLARENA® MC2000 both performed well, compared to lignin based DARACEM® 55. Both MIRA 95 and CLARENA® MC2000 had excellent slump (dosage) response, set time and 28 day compressive strengths properties. CLARENA® MC2000 had the best slump (dosage) response of the 3 admixtures tested.

Table 1 - Field Test 1 Test Data

| Admixture Type (PC= polycarboxylate) (CM= clay mitigating) |

Mid Range Water Reducer Dosage Rate |

Slump Before MRWR Added |

Slump After MRWR Added |

Dosage Response |

W/C Ratio |

Plastic Air Content |

Initial Set Time |

28 Day Compressive Strength |

| |

(oz/cwt) |

(mL/100kg) |

(in) |

(mm) |

(in) |

(mm) |

(in) |

(mm) |

|

(%) |

(hr:min) |

(psi) |

(MPa); |

| 1 - DARACEM® 55 (lignin based MRWR) |

11.3 |

736.8 |

3.1 |

78.7 |

6.9 |

175.3 |

3.8 |

96.5 |

0.52 |

2.1 |

4:55 |

5697 |

39.3 |

| 2 - MIRA® 95 (PC based MRWR) |

11.3 |

736.8 |

3.3 |

83.8 |

7.0 |

177 |

3.7 |

94.0 |

0.53 |

1.4 |

4:07 |

5993 |

41.3 |

| 3 - CLARENA® CM2000 (PC + CM MRWR) |

7.6 |

495.5 |

3.3 |

83.8 |

7.4 |

127.0 |

4.1 |

104.1 |

0.53 |

1.4 |

3:47 |

6057 |

41.8 |

Field Test 2 Arizona (Urban Ready-Mix plant

Eight 4 cubic yard batches of concrete were batched and tested. As detailed in Table 2, three chemically distinct Mid-Range Water Reducers (DARACEM® 55, MIRA® 95, CLARENA® MC2000) were tested in duplicate, with all plastic and hardened data represented by averages of the 2 tests. Mix design specifics included 451 pcy (268 kg/m3) Type V cement, 113 pcy (67 kg/m3) Type F fly ash, 1800 pcy (1068 kg/m3) ASTM C-33 #1 coarse aggregate, 1310 pcy (777 kg/m3) fine aggregate and 290 pcy (172 kg/ m3) water.

The fine aggregate sampled prior to field testing had MBV value of 1.95 mg/g and 0.85% clay, which is considered to be high, but typical for the SW region.

Field test results revealed all the mixes tested had fair slump (dosage) response. However, CLARENA® MC2000 showed significantly better slump (dosage) response, compared to lignosulfonate based DARACEM® 55 and PC based MIRA 95. Plastic air control, initial time of set and 28 day compressive strength were similar for all mixes tested.

Table 2 - Field Test 2 Test Data

| Admixture Type (PC= polycarboxylate) (CM= clay mitigating) |

Mid Range Water Reducer Dosage Rate |

Slump Before MRWR Added |

Slump After MRWR Added |

Dosage Response |

W/C Ratio |

Plastic Air Content |

Initial Set Time |

28 Day Compressive Strength |

| |

(oz/cwt) |

(mL/100kg) |

(in) |

(mm) |

(in) |

(mm) |

(in) |

(mm) |

|

(%) |

(hr:min) |

(psi) |

(MPa); |

| 1 - DARACEM® 55 (lignin based MRWR) |

11 |

717.2 |

3.1` |

78.7 |

4.3 |

109.2 |

1.2 |

30.5 |

0.53 |

1.3 |

3:25 |

3760 |

25.9 |

| 2 - MIRA® 95 (PC based MRWR) |

11 |

717.2 |

3.0 |

76.2 |

4.0 |

101.6 |

1.0 |

25.4 |

0.52 |

1.4 |

3:32 |

3840 |

26.5 |

| 3 - CLARENA® CM2000 (PC + CM MRWR) |

7.3 |

476.0 |

3.3 |

83.8 |

5.0 |

127.0 |

1.8 |

45.7 |

0.53 |

1.5 |

3:35 |

3780 |

26.1 |

In summary, field testing results showed CLARENA® MC2000’s robust dispersion capability in the presence of clay bearing aggregates resulted in consistent and predictable water reduction, excellent early and later age compressive strength, near neutral set times and superior finishability properties. CLARENA® MC2000 should be considered for use when moderate to high levels of clays are present in fine aggregates. It is always recommended laboratory and field testing be conducted to verify overall performance with specific sets of materials.