HYDRODUCT® Coil 600

Unique dual-profile drainage composite engineered to replace traditional perimeter drain systems

Product Description

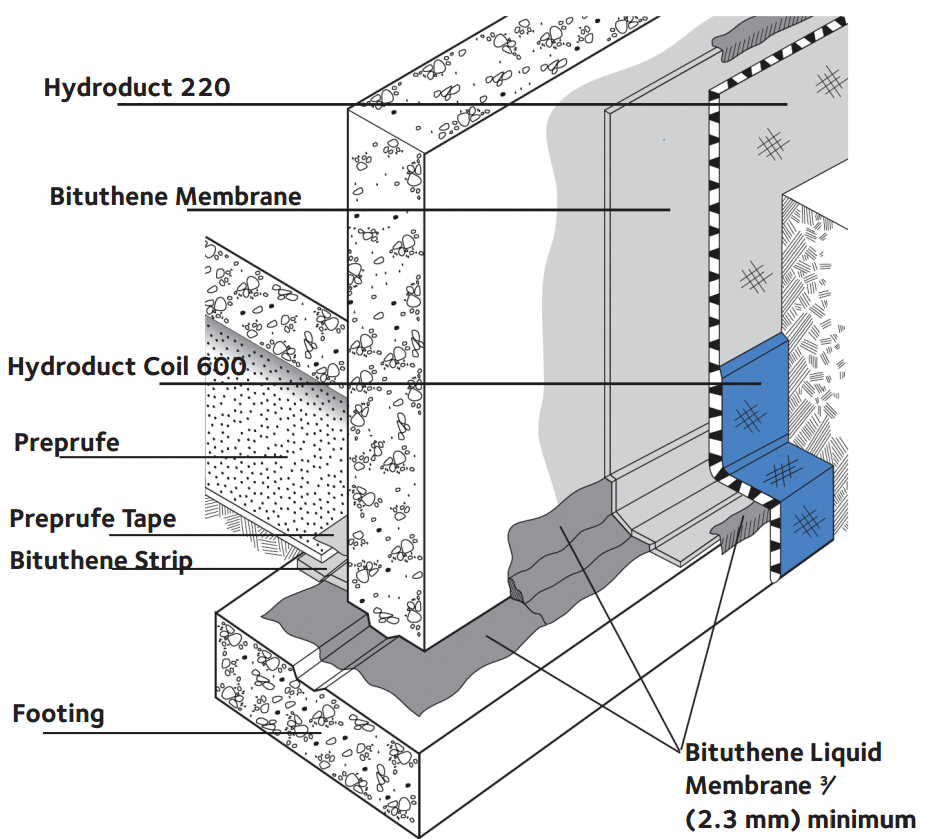

HYDRODUCT® Coil 600 consists of a combination low and high profile drainage core, a high performance geotextile and high strength backing film. The drainage core profile is 1.0 in. (25.4 mm) at the top to tie into the drainage composite system and 1 in. (25 mm) on the bottom to provide a high-flow section to transport water to the drainage exits. The geotextile serves to retain soil while allowing water to pass from the soil to the core. It is securely bonded to the core to prevent intrusion of the fabric into the core during service. The backing film ensures compatibility with the waterproofing membrane system.

Uses

HYDRODUCT® Coil 600 Perimeter Drain is used in place of traditional perimeter aggregate drain tile systems to provide an effective transport system to evacuate water from the drainage composite system and surrounding soil to the drainage exits. It is used at the base of foundation walls, retaining walls, bridge abutments, tunnels, around earth sheltered structures and under slabs.

Product Advantages

- Simple drainage system—collects ground water around sub-structures and transports to drainage exits

- High flow capacity

- Durable—unaffected by permanent immersion in water, bacteria, dilute acids, alkalis and hydrocarbons

- Economical—Light weight, easy to use; replaces expensive, imported aggregate drainage layers, pipes and geotextiles

- Geotextile fabric filter—allows ground water to pass into the drain core while restricting the movement of soil particles

- High crush strength—withstands pressures from backfilling and compaction with no loss of flow area

- Puncture and tear resistant—fabric has high strength to prevent damage during installation and operating conditions

Application Procedures

Safety, Storage and Handling Information

All construction products must be handled properly. Safety Data Sheets (SDS) are available and users should acquaint themselves with this information. Carefully read detailed precaution statements on product labels and the SDS before use.

Installation

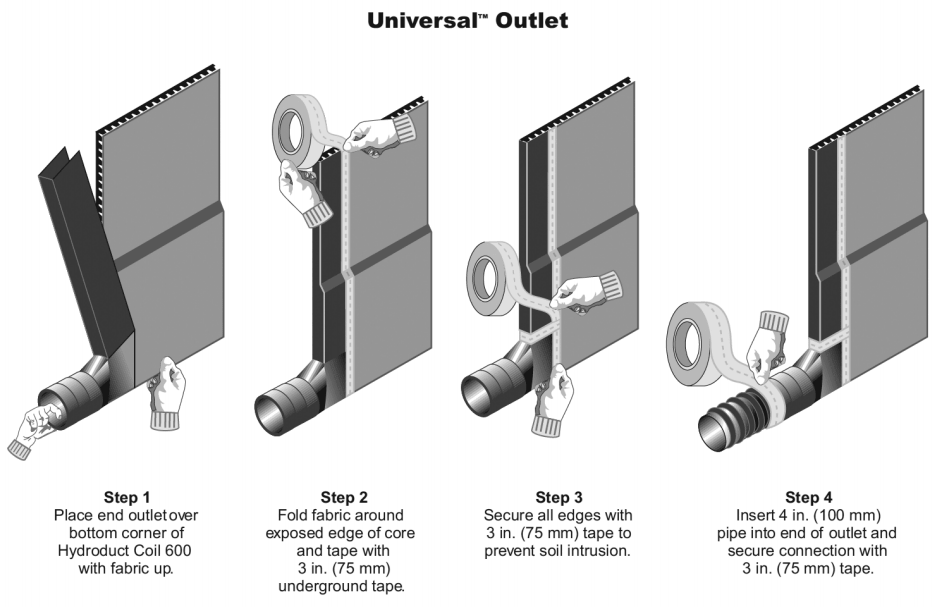

The first row of drain to be installed is the HYDRODUCT® Coil 600 at the bottom of the wall.

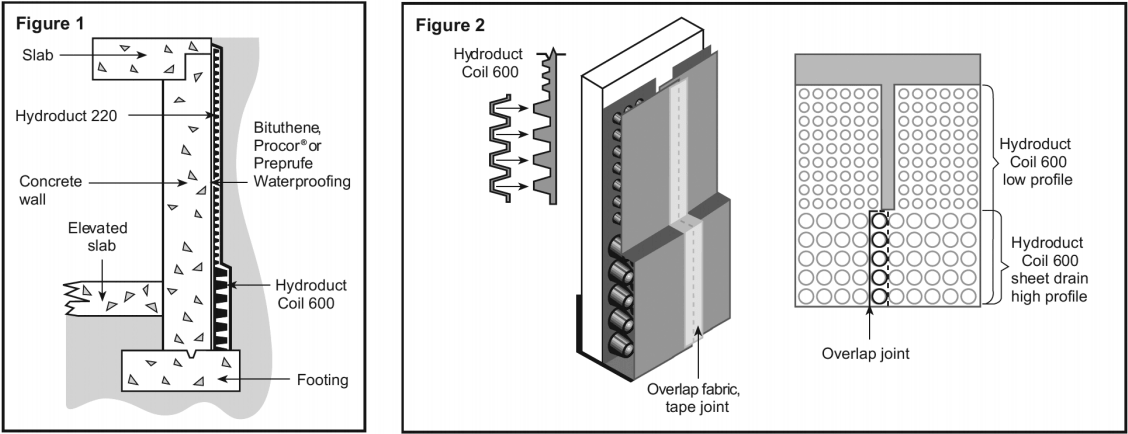

If not using HYDRODUCT® 220 for full wall coverage, close the top end of the drain to prevent soil intrusion by folding the fabric behind the drain. Close the high profile section with 3 in. (75 mm) underground tape (see Figure 1).

Attach the next roll of HYDRODUCT® COIL 600 drain by cutting one row of low profile dimples from each end of the two sections to be joined. Do not cut fabric. Interlock one row of the high profile section and secure connection.

Overlap fabric and apply 3 in. (75 mm) wide underground tape from the top to the bottom of the joint to prevent soil intrusion (see Figure 2).

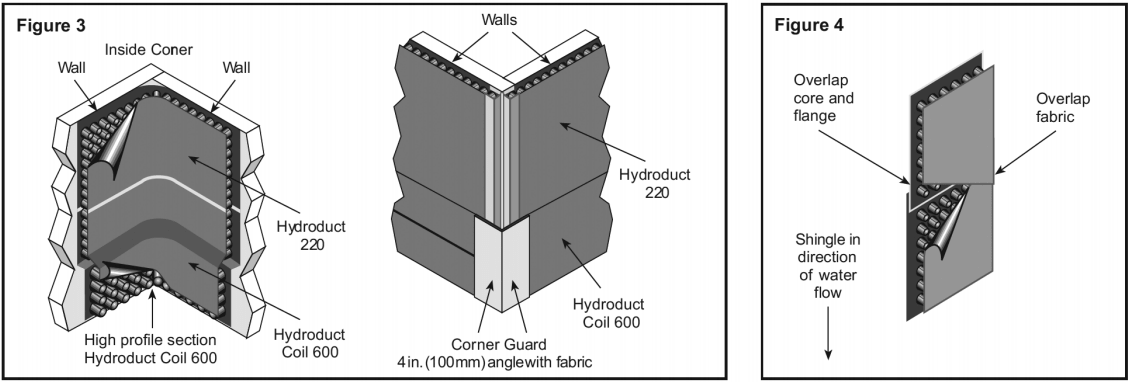

Going Around Corners

Bend drain to make inside corners. For outside corners, cut the low profile core flush with corner and tape edges. Slit fabric on high profile section, bend around corner, and place corner guard with fabric over slit of high profile drain. Secure with underground tape (see Figure 3).

Vertical Wall

When the HYDRODUCT® 220 is installed, the flange should be facing the direction opposite of the HYDRODUCT® COIL 600 water flow. When the HYDRODUCT® 220 is installed horizontally, the edge of the core with the flange should be at the top. This flange position, similar to roof shingle applications, minimizes seepage of water behind the drain. Fold back the fabric at the top of the HYDRODUCT® COIL 600 and place the HYDRODUCT® 220 on top of the HYDRODUCT® COIL 600 core flange. Fold fabric from sheet drain section down over the HYDRODUCT® COIL 600 section and secure with 3 in. (75 mm) tape.

Attaching the Next Roll of HYDRODUCT® 220

Fold back edge of fabric on lower (or downstream) drain. Do not detach from dimples. Place cones of upper (upstream) drain over flange of lower drain. Overlap fabric of upper drain over lower drain. Seal seam with 3 in. (75 mm) tape.

Overlap fabric in direction of water flow. Use tape or spray adhesive, if necessary, to keep fabric at joint in place prior to backfilling. All edges of drain should have extra fabric tucked behind core edge to prevent soil from entering core (see Figure 4).

Sealing Edges

All edges of drain should have extra fabric tucked behind core edge seal to prevent soil from entering core.

Backfilling

Soil should be placed and compacted directly against the drain. Use care during backfill operation to avoid damage to the waterproofing system. Follow generally accepted practices for backfill compacted in 6 in. to 12 in. (150 mm to 300 mm) lifts to avoid stresses on the waterproofing system. Direct compactor exhaust away from the drain to prevent damage. Backfill to a minimum of 6 in. (150 mm) above drain to allow for coverage after settlement.

Supply

| HYDRODUCT® COIL 600 | |

| Roll size | 2ft x 50ft (0.6 m x 50.29 m) roll |

| Packaging | 6 rolls/pallet (vertical orientation) |

| Weight | 28 lbs (12.7 kg)/roll |

| Ancillary Products | |

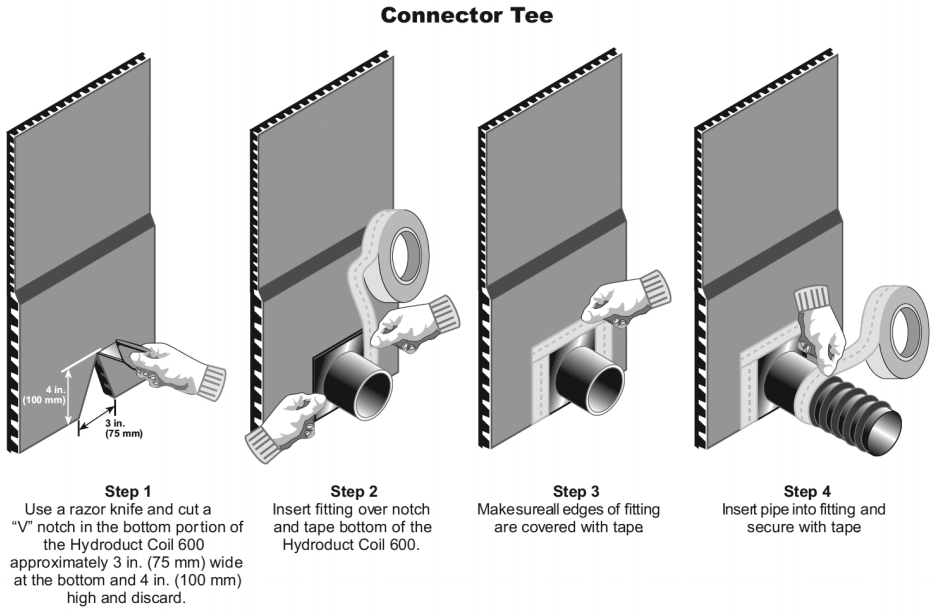

| Outlet Pipe Connector | 10/box |

| Connector Tee | 10/box |

| Corner Guard | 20/box |

| PREPRUFE® Detail Tape | 2 in. x 50 ft (50 mm x 15 m) rolls |

Physical Properties

| PROPERTY | TYPICAL VALUE | TEST METHOD |

| Drainage Core | ||

| Thickness | 1.0 in. (25.4 mm) nominal | ASTM D5199 |

| Compressive strength | 9,000 lbs/ft2 (431 kPa) | ASTM D6364 |

| Flow rate (gradient 1.0) | 21 gal/min./ft (261 L/min./m) | ASTM D4716 |

| Geotextile | ||

| Tensile strength | 115 lbs (512 N) | ASTM D4632 |

| Apparent opening size | 70 U.S. sieve (.21 mm) | ASTM D4751 |

| Flow rate | 150 gal/min./ft2 (6113 L/min./m2) | ASTM D4491 |

| CBR puncture | 320 lbs (1.43 kN) | ASTM D6241 |

For Horizontal Plazas

Place drain with fabric side up. Cut core and fabric to fit tightly around floor drain.

Installation Under Slabs

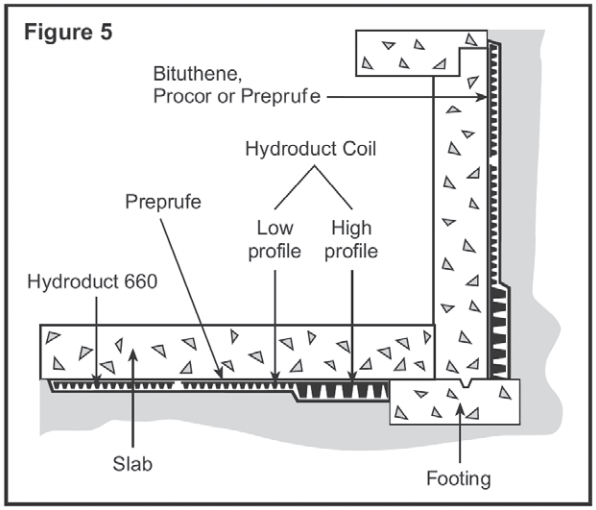

For under floor slab installation, position HYDRODUCT® Coil 600 sheet drain as shown with geotextile to soil side (see Figure 5).

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

HYDRODUCT and PREPRUFE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2021 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-09-16

https://ca.gcpat.com/fr-ca/solutions/products/hydroduct-drainage-composite/hydroduct-coil-600