INJECTO®

Groutable Hose Waterstop System

Product Description

INJECTO® is an injectable waterstop system that provides a conduit for the placement of GCP Applied Technologies chemical grouts. The ½” (12mm) permeable tube is installed before the concrete pour, but not injected until after the shrinkage associated with the curing concrete process is complete (typically a minimum 28-day cure). This allows the cracks to open fully before permanently sealing the interfaces and voids within construction joints, pipe penetrations, slurry walls and slab connections with chemical grout.

Figure 1. INJECTO® Kit

Product Advantages

- Fast, simple installation

- No special tools required

- Low pressure injection

- Permanent seal after injection

- Injectable any time after concrete cure

Applications

- Sealing cold and construction joints

- Sealing pipe penetrations and details

- Sealing joints between slurry walls and slabs

INJECTO® Tubes should only be used with GCP DE NEEF® INJECTO® PURe and DE NEEF® Flex Cat PURe chemical grouts. Please see different product data sheet and contact your local sales representative or technical services consultant for more details.

Packaging & Handling

INJECTO® is supplied in 100 ft. kits to allow the system to be cut to length on site. The maximum recommended cut length of INJECTO® Tube to be installed between packers is 25 ft. (7.6 m)

(see Figure 1).

| Yellow INJECTO® Tube: | 100 ft. (30,5 m) |

| Clear PVC Packer Tubing : | 18 ft. (5.5 m) |

| Blue trumpets: | 12 pieces |

| Anchoring clips: | 100 pieces |

1 Pallet = 40 x 100 ft. kits = 4000 ft. (1219 ft)

Unlimited shelf life when stored in a dry place.

Properties

| Typical Properties | |

|---|---|

| Outside Diameter | 1/2 in. (12.5 mm) |

| Inside Diameter | 5/16 in. (8mm) |

| Length | Maximum 25 ft (7.6 m) |

| Weight | 4.5 lbs (2 kg) per 25 ft (2 kg per 7.6 m) |

| Operating temperature | Up to 158°F (70°C) |

| Tensile strength steel wire | Approx. 261,000 psi (1800N/mm2) |

| Diameter filter pores | 35 microns |

Installation Guidelines

A high strength spiral wire coil (1) prevents collapse during concrete placement, while the non-woven filter membrane (2) prevents the tube from being clogged with concrete particles. A bright yellow reinforced mesh sleeve (3) protects the tube and allows for easy inspection before the pour. Wherever old to new concrete surfaces join, the INJECTO® system can be easily installed (see Figure 2).

J

Figure 2. INJECTO® Tube Construction

The yellow INJECTO® Tube is installed onto the hardened concrete during formwork installation. In the case of rough surfaces, any gap between INJECTO® Tube and the surface should be filled with SWELLSEAL® WA or PREPRUFE® Hydrophilic Sealant.

The yellow INJECTO® Tube is cut to the required length on the job site (recommended length 25 ft. or less). The cut ends are smoothed with a twist; then the blue trumpets are installed over the yellow INJECTO® Tube and screwed down to the stop mark inside the trumpet (Figure 3).

Figure 3. INJECTO® Tube shown with blue trumpets. INJECTO® Packer and Formholder Packer are not included in standard INJECTO® Tube “kit”

The yellow INJECTO® Tube is attached to the concrete with anchoring clips between the inner and outer reinforcing bars. Attach the anchoring clips to the concrete every 12 inches with concrete anchors or nails applied with a powder actuated system (see Figures 4, 5, 6 & 7).

Figure 4. Anchoring clips on INJECTO®

Figure 5. Nailing anchor clips

Figure 6. Placement of anchor clips

Figure 7. End and beginning of INJECTO® Tube lengths

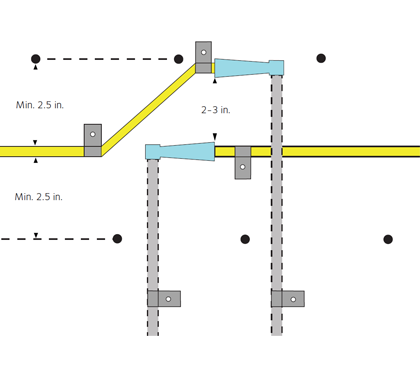

The blue trumpets provide a connection between the yellow INJECTO® Tube and the clear packer tubing. Trumpets on adjacent runs should be installed with the wide ends of the trumpets (where the yellow INJECTO® Tube is attached) in line with each other and the two trumpets separated by 2-3 inches (see Figure 7). This will help avoid cross contamination of the yellow INJECTO® Tubes during the grouting operation.

Always terminate the yellow INJECTO® Tube into a trumpet with a clear braided tube run to above grade. Allow for a minimum of 12” of concrete cover at the surface and keep the injecto tube a minimum of 6” away from Preprufe or any waterproofing membranes (expansion of the grout may delaminate the membrane). Do not run the yellow INJECTO® Tube outside of the formwork or to day light (this will create the injecto tube ineffective and non-functional).

Attach the clear packer tubing over the barbed end of the trumpets. Then cut the appropriate length of packer tubing as required to reach a formholder packer or to extend outside the formwork. The clear packer tubing should be secured to the rebar with tie wire to prevent movement during the pour.

The formholder packers can be either nailed to wooden formwork or attached to the rebar with steel tie wire if metal forms are used. If formholder packers are used, attach the clear packer tubing directly to them. If the clear packer tubing is being run outside the formwork, protect the open ends with a plastic cap or tape and take measures to protect them from damage during formwork, installation and stripping.

The INJECTO® System is ideal for unique and problem details such as pipe penetrations and attachment to conventional PVC waterstops that may encounter very high head pressures (see Figures 8 and 9).

Figure 8. Pipe Sealing

Figure 9. PVC Waterstop

CAUTIONS

- The yellow INJECTO® Tube must be installed in direct contact with the joint over its full length, to allow proper and complete distribution of the injection resin. If the concrete is not smooth enough to allow full contact, use SWELLSEAL® WA to create a smooth surface. Press the INJECTO® Tube into the SWELLSEAL® WA.

- Do not cross the yellow INJECTO® Tubes. Yellow should never touch yellow or cross contamination could occur during the grouting operation.

- Ends and beginnings of yellow INJECTO® Tube lengths should have trumpets spaced 2-3 inches apart (see Figures 4 and 8). This is to prevent cross-contamination during the resin injection process.

- Concrete coverage must be a minimum of 2 ½” on all sides. After concrete has cured for the recommended 28 days, any water infiltrating into the joint will be collected by the system and appear through the clear packer tubing. The tubing should either protrude out of the concrete at easily accessible places or be connected to a formholder packer.

The INJECTO® system is designed to provide a delivery system for GCP waterproofing resins, which are injected into the structure in accordance with the instructions found in the selected injection resins technical data sheets. Consult with GCP Technical Services for assistance in selecting the appropriate chemical grout for each condition.

Health and Safety

Read and understand the product label and Safety Data Sheet for each system component before use. All users should acquaint themselves with this information prior to working with the material. Carefully read detailed precaution statements on the product labels and SDS before use. SDS’s can be obtained from our web site at gcpat.com or by contacting GCP toll free at 1-866-333-3SBM (3726).

Limitations

The INJECTO® waterstop system must be installed by an Approved GCP Applicator. In accordance with the INJECTO® Manual, Concrete cover must be a minimum of 2 ½” on all sides.

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

INJECTO, SWELLSEAL and PREPRUFE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

GCP0083 WS-001-0617 INJECTO

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-09-16

https://ca.gcpat.com/fr-ca/solutions/products/waterstops/injecto