BITUTHENE® 3000 and BITUTHENE® Low Temperature Membranes

For above grade plaza and parking decks and below grade basements, tunnels and other subterranean applications

Product Description

BITUTHENE® 3000 and BITUTHENE® Low Temperature Membranes are self-adhesive, rubberized asphalt/polyethylene waterproofing membranes for elevated plaza and parking decks and below grade basements, tunnels, and other subterranean applications.

GCP Applied Technologies’ (“GCP”) BITUTHENE® 3000 and BITUTHENE® 3000 Low Temperature Membranes combine a robust, flexible, pre-formed high performance, cross laminated, HDPE carrier film with a tacky, self-adhesive rubberized asphalt compound specifically designed to adhere to cured concrete surfaces.

Product Advantages

- Specifically designed as a barrier to water, moisture, and gas by physically isolating the structure from the surrounding substrate

- Cross laminated film is dimensionally stable, with high tear strength, puncture, and impact resistance

- Cold applied – No flame hazard; self-adhesive overlaps designed to provide membrane continuity

- Chemically resistant to most soil conditions, membrane is designed to provide effective external protection against aggressive soils and groundwater

- Flexible – Elongation in excess of 300% helps accommodate minor settlement and shrinkage movement

- Controlled thickness – Factory-made sheet allows for constant, non-variable site application

- RIPCORD® integrated filament split release on demand – Ease of membrane positioning in detailed areas

- Wide application window -

- BITUTHENE® low temperature membrane when surface and ambient temperatures are between 25°F (-4 °C) and 60°F (16 °C)

- BITUTHENE® 3000 membrane for use when surface and ambient temperatures are at 40 °F (5°C) or above

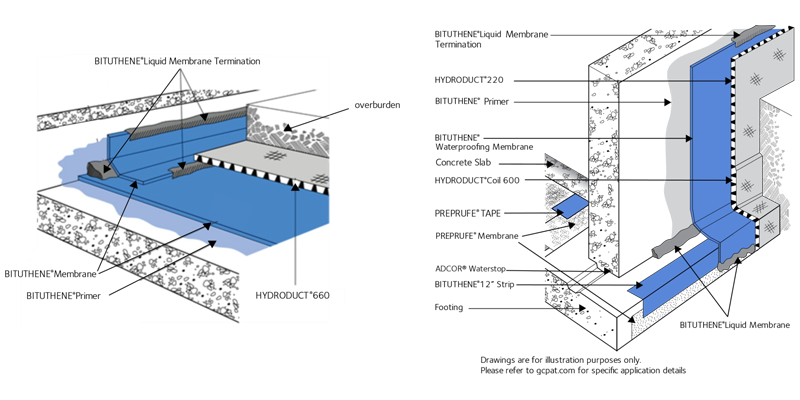

System Components

Membranes

- BITUTHENE® 3000 membrane for application to surfaces at ambient temperatures of 40 °F (5°C) or above

- BITUTHENE® low temperature membrane for low temperature applications when surface and ambient temperatures are between 25 °F (-4 °C) and 60°F (16 °C)

Ancillary Components (the most current Data Sheets for all system components are available on gcpat.com)

- BITUTHENE® primer adhesive B2 LVC - Low VOC, solvent-based primer to increase adhesion of BITUTHENE® 3000 membrane to concrete surfaces

- BITUTHENE® liquid membrane – Two component, elastomeric, liquid applied detailing compound

- BITUTHENE® mastic – Rubberized asphalt-based mastic

- PREPRUFE® Detail Tape – Double-sided, self-adhesive tape

- HYDRODUCT® drainage sheet - High impact and creep resistant geo-composite and protection layer

Limitations of Use

- Approved uses only include those uses specifically detailed in this product data sheet and other current product data sheets that can be found at gcpat.com.

- BITUTHENE® membranes are not intended for any other use. Contact GCP Technical Services where any other use is anticipated or intended.

- BITUTHENE® membranes are designed where in-service temperatures will not exceed 130 °F (54°C).

- Do not use BITUTHENE® mastic to terminate BITUTHENE® membranes to PREPRUFE® pre-applied waterproofing systems. Terminations to PREPRUFE® membranes should only be done with BITUTHENE® liquid membrane.

- Do not apply BITUTHENE® Membranes over insulation or lightweight insulating concrete

Special Note: When this information is printed from the gcpat.com website, a footer appearing on this document will restrict its applicability to the United States. Note that the information and references in this document is hereby expanded and applied to North, Central and South America.

Safety and Handling Information

Users must read and understand the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office, by calling GCP toll free at 1-866-333-3SBM (3726) and in some cases from our web site at gcpat.com.

Storage

- All BITUTHENE® membranes can be stored horizontally inside the box

- Observe one-year shelf life and use on a first in, first out basis.

- Store in dry conditions between 40°F (4.5°C) - 90°F (32°C).

- Store off ground, under tarps, or otherwise protected from rain and ground moisture.

- See Technical Letter #TL-0030 Shelf Life/Storage and Handling of GCP Waterproofing.

Installation

Technical Support, Details and Technical Letters

The most up to date detail drawings and technical letters are available at gcpat.com. For complete application instructions, please refer to the current GCP Applied Technologies Contractor Handbook and Literature on (www.gcpat.com). Documents in hardcopy as well as information found on websites other than www.gcpat.com may be out of date or in error. Before using this product, it is important that information be confirmed by accessing www.gcpat.com and reviewing the most recent product information, including without limitation product data sheets and contractor manuals, technical bulletins, detail drawings and detailing recommendations. Please review all materials prior to installation of BITUTHENE® 3000 membrane. For technical assistance with detailing and problem solving please call toll-free at (866) 333-3SBM (3726).

Temperature

- Apply BITUTHENE® 3000 membrane only in dry weather and when air and surface temperatures are 40°F (5°C) or above.

- Apply BITUTHENE® low temperature membrane only in dry weather and when air and surface temperatures are 25°F (-4°C) to 60°F (16°C).

- Apply BITUTHENE® adhesive primer B2 LVC in dry weather above 25°F (-4°C). (See separate product information sheet.)

Surface Preparation

Surfaces must be structurally sound and free of voids, spalled areas, loose aggregate and sharp protrusions. Remove contaminants such as grease, oil and wax from exposed surfaces. Remove dust, dirt, loose stone and debris. Concrete must be properly cured (minimum 7-days for normal structural concrete and 14-days for lightweight structural concrete). For horizontal applications, double the above cure times of concrete if placed over non-vented decks. Certain conditions may require longer dry times, such as unusually wet weather or late removal of forms.

On vertical applications if time is critical, BITUTHENE® Adhesive Primer B2 LVC may be used to allow priming and installation of membrane on damp surfaces or green concrete. Priming may begin in this case as soon as the concrete will maintain structural integrity. Use form release agents which will not transfer to the concrete. Remove forms as soon as possible from below horizontal slabs to prevent entrapment of excess moisture. Excess moisture may lead to blistering of the membrane. Cure concrete with clear, resin-based curing compounds which do not contain oil, wax or pigment. See Technical Letter #TL-0005 Curing Compounds and Form Release Agents. Except with BITUTHENE® Adhesive Primer B2 LVC, allow concrete to thoroughly dry following rain. Do not apply any products to frozen concrete.

Repair defects such as spalled or poorly consolidated areas. Remove sharp protrusions and form match lines. For rough or uneven deck surfaces use BITUTHENE® Deck Prep as a repair and leveling agent. See Above Grade Waterproofing BITUTHENE® Deck Prep product information sheet for details. On masonry surfaces, apply a parge coat to rough concrete block and brick walls or trowel cut mortar joints flush to the face of the concrete blocks.

Priming

- Apply BITUTHENE® adhesive primer B2 LVC by a lamb’s wool roller at a coverage rate of 325–425 ft2/gal (7.5–10.0 m2/L). Allow primer to dry one hour or until tack-free.

- Dry time may be longer in cold temperatures. Re-prime areas if contaminated by dust. If the work area is dusty, apply membrane as soon as the primer is dry. In general, priming should be limited to what can be covered within 24-hours

- Do not apply any primer onto BITUTHENE® membrane.

Application on Horizontal Surfaces

(Note: PREPRUFE® pre-applied membranes are recommended for below slab or for any application where the membrane is applied before concreting. See PREPRUFE® waterproofing membrane product information sheets.)

All horizontal surfaces should be sloped to drain at least 1/8 in. /ft. (11 mm/m). When a minimum slope of 1/8 in./ft. (11 mm/m) cannot be achieved, 2 layers of BITUTHENE® Membrane or 80-mils of BITUTHENE® Deck Prep and 1-layer of BITUTHENE® Membrane may be an option, contact your local GCP representative.

Apply membrane from the low point to the high point so that laps shed water. Overlap all seams at least 2.5 in. (65 mm). Stagger all end laps. Roll the entire membrane firmly and completely as soon as possible. Use a linoleum roller or standard water-filled garden roller less than 30 in. (760 mm) wide, weighing a minimum of 75 lbs (34 kg) when filled. Cover the face of the roller with a resilient material such as a 1/2 in. (13 mm) plastic foam or two wraps of indoor-outdoor carpet to allow the membrane to fully contact the primed substrate. Seal all T-joints and membrane terminations with BITUTHENE® Liquid Membrane by the end of the day.

Application on Vertical Surfaces

Apply membrane in lengths up to 8 ft (2.5 m). Overlap all seams at least 2.5 in. (65 mm). On higher walls apply membrane in two or more sections with the upper overlapping the lower by at least 2.5in. (65 mm). Roll all membrane with a hand roller.

Terminate the membrane at grade level. Press the membrane firmly to the wall with the butt end of a hardwood tool such as a hammer handle or secure into a reglet. Failure to use heavy pressure at terminations can result in a poor seal. All top of wall terminations must be sealed with BITUTHENE® Liquid Membrane or BITUTHENE® Mastic. A termination bar may be used to ensure a tight seal. At the end of each working day, if the wall has been only partially covered, apply a maximum 1/4 in. bead of BITUTHENE® Mastic tooled thin or BITUTHENE® Liquid Membrane along the exposed edges of the membrane at its temporary terminations to prevent vertical drainage of precipitation undermining the membrane adhesion. Terminate the membrane at the base of the wall if the bottom of the interior floor slab is at least 6 in. (150 mm) above the footing.

Otherwise, use appropriate inside corner detail where the wall and footing meet. A 1/8 in. (3 mm) x 1 in. (25 mm) aluminum termination bar aligned with the top of the membrane is recommended for terminations on CMU, in earth covered decks, and in earth bermed applications where soil cannot be fully compacted. See Technical Letter #TL-0026 BITUTHENE® Membrane Terminations for additional information.

Membrane Repairs

Patch tears and inadequately lapped seams with the same membrane as used on the surrounding surface. Clean the in place membrane with a damp cloth and completely dry. Slit fishmouths and repair with a patch extending 6 in. (150 mm) in all directions from the slit and seal edges of the patch with BITUTHENE® Liquid Membrane. Inspect the membrane thoroughly before covering and make all repairs prior to testing, covering or backfilling.

Flood Testing (Horizontal Surfaces Only)

- Flood test all horizontal applications with a minimum 2 in. (51 mm) head of water for 24-hours. Mark any leaks and repair when the membrane is dry. Before flood testing, be sure the structure will withstand the dead load of the water. For sloped decks,it may be necessary to segment the flood test to avoid deep water near drains.

- Conduct the flood test 24-hours after completing the application of BITUTHENE® waterproofing system. Immediately after flood test is completed, and all necessary repairs made, install drainage composite to protect the BITUTHENE® Membrane from traffic and other trades.

- As an alternate to flood testing, appropriate electronic leak detection may be used to check the integrity of the system.

Drainage

HYDRODUCT® drainage composites are recommended for both active drainage and protection of the membrane. See HYDRODUCT® product data sheet at gcpat.com.

Insulation

Always apply BITUTHENE® Membrane directly to primed or conditioned structural substrates. Insulation, if used, must be applied over the membrane. Do not apply BITUTHENE® Membranes over insulation or lightweight insulating concrete.

Protection of Membrane

Protect BITUTHENE® Membranes to avoid damage from other trades, construction materials or backfill. At temperatures above 77°F (25°C) to avoid potential formation of blisters place protection immediately.

- On vertical applications, use HYDRODUCT® 220 drainage composite. Adhere HYDRODUCT® 220 drainage composite to membrane with PREPRUFE® Detail Tape. Alternative methods of protection are to use 1 in. (25 mm) extruded polystyrene or 1/4 in. (6 mm) asphaltic hardboard. Such alternatives, however, do not provide positive drainage to the system. Adhere polystyrene protection board with PREPRUFE® detail tape. See Technical Letter #TL-0027, Protection Courses Used with GCP Waterproofing Systems for additional information.

- HYDRODUCT® 220 drainage composite is for vertical use only

- On horizontal applications, use HYDRODUCT® 660 drainage composite. Alternate methods of protection are to use 1 in.(25mm) extruded polystyrene or 1/4 in. (6 mm) asphaltic hardboard. Such alternatives, however, do not provide positive drainage to the system.

Placing Steel

On horizontal applications when placing steel over properly protected membrane, use concrete bar supports (dobies) or chairs with plastic tips or rolled feet to prevent damage from sharp edges. Use special care when using wire mesh, especially if the mesh is curled.

Backfill

Place backfill as soon as possible. (See Protection of Membrane section above.) Use care during backfill operation to avoid damage to the waterproofing system. Follow generally accepted practices for backfilling and compaction. Backfill should be added and compacted in 6 in. (150 mm) to 12 in. (300 mm) lifts.

Approvals

- City of Los Angeles Research Report RR 24386

- Miami-Dade County Code Report NOA 18-1109.01

- U.S. Department of Housing and Urban Development (HUD) HUD Materials Release 628

- BITUTHENE® 3000 membranes carry an Underwriters’ Laboratory Class A Fire Rating (Building Materials Directory, (File TFGU.R7910) when used in either of the following constructions:

- Limited to noncombustible decks at inclines not exceeding 1/4 in. (6 mm) to the horizontal 1 ft (0.3 m). One layer of BITUTHENE® waterproofing membrane, followed by one-layer of 1/8 in. (3 mm) protection board, encased in 2 in. (50 mm) minimum concrete monolithic pour.

- Limited to noncombustible decks at inclines not exceeding 1/4 in. (6 mm) to the horizontal 1 ft (0.3 m). One layer of BITUTHENE® waterproofing membrane, followed by one layer of DOW Styrofoam PD Insulation Board [2 in. (50 mm) thick]. This is covered with one layer of 2 ft x 2 ft x 2 in. (0.6 m x 0.6 m x 50 mm) of concrete paver topping.

Supply

| BITUTHENE® 3000 and BITUTHENE® Low Temperature Membranes | |

| Roll Dimensions1 | 3ft x 66.7ft roll (200ft2) [0.9m x 20m (18.6m2)] |

| Roll weight | 83Ibs. (38kg) gross |

Ancillary Components (the most current Data Sheets for all system components are available on gcpat.com)

Physical Properties: (BITUTHENE® 3000 & BITUTHENE® Low Temperature Waterproofing Membranes)

| PROPERTY | TYPICAL VALUE | TEST METHOD |

| Color | Dark gray-black | |

| Roll Dimensions3 | 3 ft x 66.7 ft roll (200 ft2) | |

| Thickness | 60 mils (1.5 mm) nominal | ASTM D3767 - method A |

| Flexibility, 180° bend over 1 in. (25 mm) mandrel at -25°F (-32°C) |

Unaffected | ASTM D1970 |

| Tensile strength, membrane, die C | 325 psi (2240 kPa) | minimum ASTM D4121 |

| Tensile strength, film | 5,000 psi (34.5 MPa) minimum | ASTM D8821 |

| Elongation, ultimate failure of rubberized asphalt | 300% minimum | ASTM D4121 |

| Crack cycling at -25°F (-32°C), 100 cycles | Unaffected | ASTM C836 |

| Lap shear | 20 lbs (89 N) | ASTM D10022 |

| Peel strength | 9 lbs/in. (1576 N/m) | ASTM D903 |

| Puncture resistance, membrane | 50 lbs (222 N) minimum | ASTM E154 |

| Resistance to hydrostatic head | 230 ft (70m) of water | ASTM D5385 |

| Permeance | <0.1 perms | ASTM E96, section 12 - water method |

| Water absorption | <0.1% | ASTM D570 |

1. The test is run at a rate of 2 in. (50 mm) per minute.

2. The test is conducted at 4 in. (102 mm) per min.

3. Individual roll length may vary +/- 1%

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation or suggestion is intended for any use that would infringe any patent, copyright or other third-party right.

BITUTHENE, BITUTHENE DECK PREP, HYDRODUCT, PREPRUFE and RIPCORD are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2019 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-09-16

https://ca.gcpat.com/en/solutions/products/bituthene-post-applied-waterproofing/bituthene-3000-and-bituthene-low