ELIMINATOR® bridge deck waterproofing membrane

Extending the life of road and railway bridges

Superior protection for bridge decks

Steel and concrete bridges are vulnerable to attack by water, chloride and frost, leading to deterioration and even structural failures. Installing a high-performance waterproofing membrane is therefore an essential part of any bridge construction or refurbishment program. The ELIMINATOR® bridge deck waterproofing membrane is a cold, spray-applied solution that can outlast the life of the structure — reducing maintenance costs and traffic disruptions.

ELIMINATOR® Product Documents

| Product Name | Product Data Sheet |

| ELIMINATOR® |

Products

- Product Name

- Description

- Key Benefits

- Applications Type

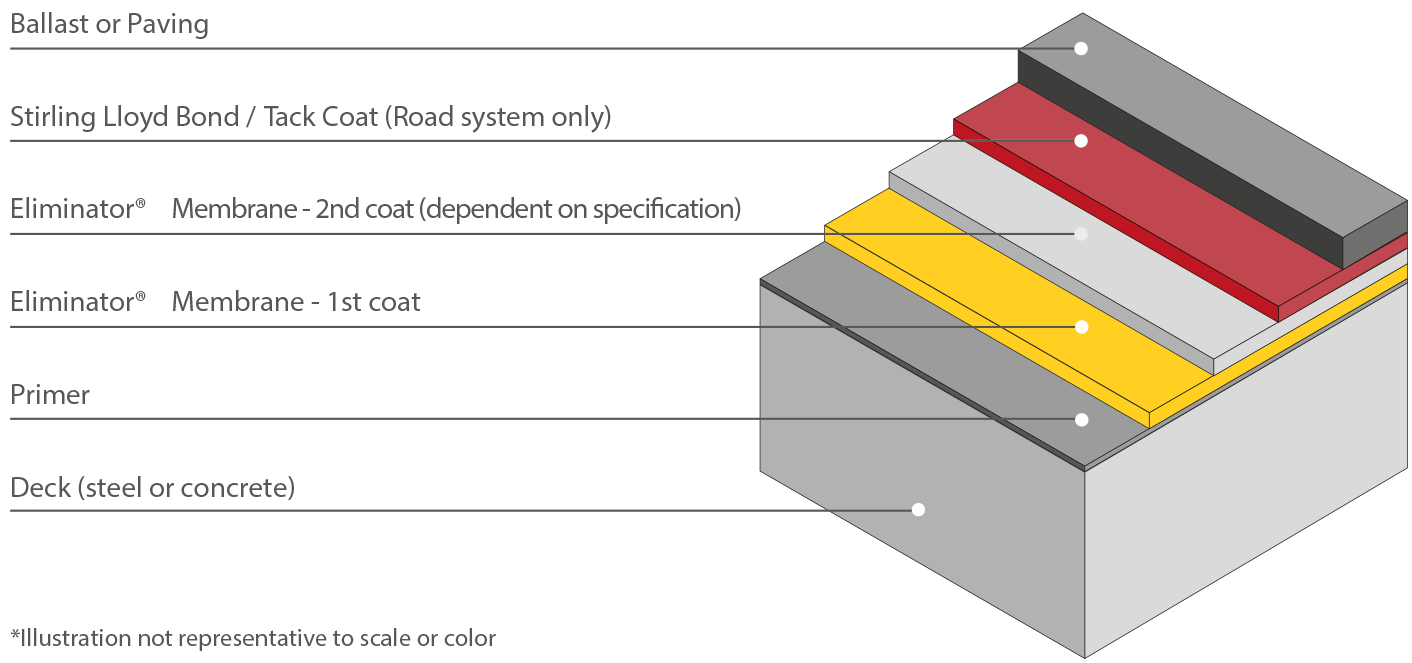

ELIMINATOR® is a high performance waterproofing membrane for the protection of concrete and steel bridge decks based on Stirling Lloyd, now GCP’s unique ESSELAC® advanced resin technology and extensive experience in the development of coatings for specialist waterproofing.

- Long and effective life

- Able to withstand high humidity and cures rapidly even at low temperatures enabling all year round application

- Rapid application and re-access

- Concrete Bridge Decks

- Steel Bridge Decks

- Bridge Piers

- Bridge Service Ducts

- Culverts

Achieve long-term performance

The ELIMINATOR® bridge deck waterproofing membrane has an unparalleled track record protecting thousands of concrete and steel bridges throughout the world. Based on unique ESSELAC® advanced resin technology, the system creates composite action between the deck, waterproof membrane, substrate and asphalt, ensuring that the membrane is fully bonded both downwards to the deck and upwards to the surfacing. The extremely high bond enables the membrane to stand up to punishing climate conditions and heavy traffic loads.

Accelerating waterproofing application

The ELIMINATOR® bridge waterproof membrane offers fast, simple and effective application. Unlike alternative solutions that are sensitive to moisture, the ELIMINATOR® membrane can be applied virtually year round, in any climate, preventing costly weather delays. It cures in just an hour, even in high humidity or low temperatures. In addition, the system features on-the-spot QA capabilities, such as the two-color application system, that make it easy to quickly verify that the membrane is applied properly.

Product Advantages

- Long lasting, highly durable membrane drives down future maintenance costs

- Fast application (in excess of 2,000m2 per day) with industry-standard equipment

- No need for hot trades

- Requires minimal surface preparation

- Approved Contractor Program and onsite quality control measures ensure the integrity of the membrane prior to surfacing

- Elimination of critical overcoating time allows phasing of work for greater scheduling flexibility

- Unaffected by application of surfacing up to 250°C