HYDRODUCT® Drainage Composite

Robust membrane protection for efficient water deflection.

Roofs, green roofs, basements, retaining walls, tunnels and more — the one thing that these have in common is the risk of leaks. GCP waterproofing membranes are industry leaders, but drainage composites add even more durability. There's a HYDRODUCT® drainage solution to complement every form of our waterproofing membranes, and they're a critical component of any well-designed and complete waterproofing system.

HYDRODUCT® Product Documents

| Product Name | Product Data Sheet |

| HYDRODUCT® 220 | |

| HYDRODUCT® 225 | |

| HYDRODUCT® 660 | |

| HYDRODUCT® Coil 600 | |

| HYDRODUCT® 500RS Data Sheet |

Products

- Product Name

- Description

- Key Benefits

- Applications Type

HYDRODUCT® 220 is a strong, preformed 0.44 in. (11 mm) thick geocomposite drainage sheet system, comprising a hollow studded polypropylene core, covered on one side with a nonwoven, needle punched polypropylene filter fabric and on the other side with a smooth polymeric film.

- Enhances waterproofing—eliminates hydrostatic pressure build-up

- Efficient water collector/deflector—can be used as a sandwich drainage layer between lagging and the reinforced concrete structure

- Smooth polymeric sheet—compatible with PREPRUFE ® , PROCOR ® , or BITUTHENE ® membranes Simple

HYDRODUCT® 220 is designed primarily for use with waterproofing materials in vertical installations.

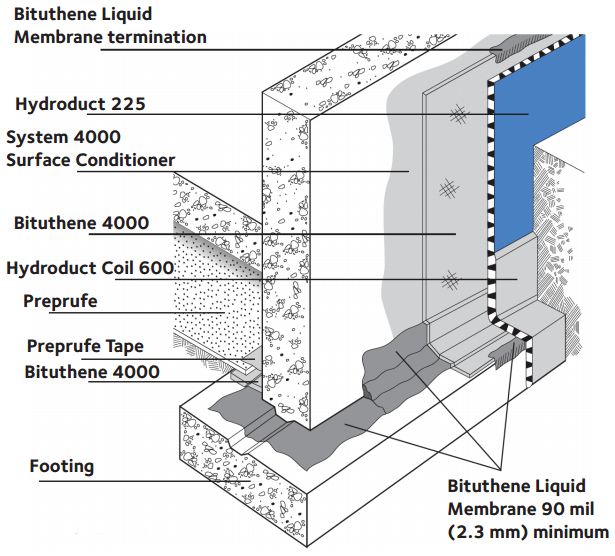

HYDRODUCT® 225 consists of a nominal 0.4 in. (10.16 mm) drainage core, a high performance geotextile and a high strength backing film.

- Hydrocarbon resistant—suitable for contaminated environments

- Heat resistant—use below hot asphalt bedding for pavers Enhances

- waterproofing—eliminates hydrostatic pressure build-up

HYDRODUCT® 225 is designed to collect and transport water in hydrocarbon contaminated environments.

HYDRODUCT® 660 is a highly robust, preformed, 0.44 in. (11 mm) thick geocomposite drainage sheet system, comprising a heavy duty, studded polypropylene preformed membrane.

- Universal horizontal application—suitable for all overburdens including concrete

- Damage and creep-resistant—high compressive strength core resists traffic loads and site damage to maintain drainage flow

- High flow capacity—drains 23 gal/min./ft (286 L/min./m) width

HYDRODUCT® 660 Drainage Composite is designed to collect and transport water to drainage outlets.

HYDRODUCT® Coil 600 consists of a combination low and high profile drainage core, a high performance geotextile and high strength backing film.

- Simple drainage system—collects ground water around sub-structures and transports to drainage exits

- High flow capacity—drains 140 gals/min./ft (5704 L/min./m)

- Durable—unaffected by permanent immersion in water, bacteria, dilute acids, alkalis and hydrocarbons

HYDRODUCT® Coil 600 Perimeter Drain is used in place of traditional perimeter aggregate drain tile systems to provide an effective transport system to evacuate water from the drainage composite system and surrounding soil to the drainage exits.

HYDRODUCT® 500RS green roof composites are a highly robust, preformed geocomposite drainage and root barrier sheet system designed for green roof applications.

HYDRODUCT® Green Roof Composites are designed for horizontal green roof applications.

A versatile drainage portfolio

HYDRODUCT® products are designed for a variety of applications, from green roofs to basement subfloors. Here are just a few of the HYDRODUCT® products currently available.

HYDRODUCT® 660

Designed for all horizontal applications, HYDRODUCT® 660 collects and transports water to drainage outlets. This high strength non-woven geotextile is designed to protect the drainage composite during and after construction. In addition, the material enhances waterproofing by draining 17 gallons per minute per foot of width. Lastly, the material makes life easier for contractors by being lightweight, easy to install, and compatible with both sheet and waterproofing membranes.

HYDRODUCT® 200

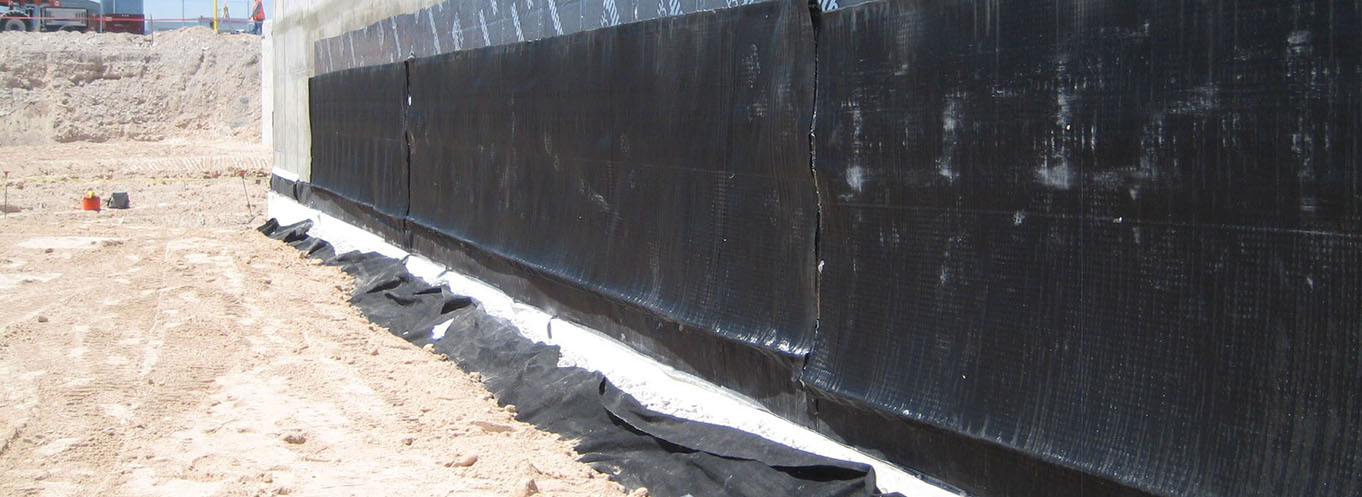

HYDRODUCT® 200 is specifically designed for use on substructures—retaining walls, foundation walls, bridges, tunnels, and planters. HYDRODUCT® 200 can be applied both vertically and horizontally—the rot-proof geotextile performs just as well either way.

HYDRODUCT® Green Roof Composite

Designed for horizontal green roofs, this HYDRODUCT® product shields roof decks from both water and root penetration. The barrier is treated with a natural root inhibitor, and is specifically shaped to redirect roots away from the drainage core. Additionally, the system is designed to capture and store excess water from the growth medium until it can be re-absorbed. Compatible with both the PROCOR® and BITUTHENE® deck systems, this system supports gardens and eco-friendly buildings while protecting concrete at the same time.

Contractor References

Find application instructions, installation details and detailed drawings.

Distributor Locator

Looking for a distributor that supplies air barriers, flashing, weather resistive barriers, roofing underlayments, waterproofing, injection materials or flooring?

Product Warranty

Click on the login to access the site with your username and password. Please add GCPAT\ (including the slash) in front of your user name when entering user name. If you need assistance, please contact Denise White at: 617 498-4555 or Denise.I.White@gcpat.com