PREPRUFE® 800PA Post-Applied Membrane Data Sheet

A self-adhered waterproofing membrane with an aggressive, synthetic non-asphaltic adhesive, for basement walls in open excavation.

Product Description

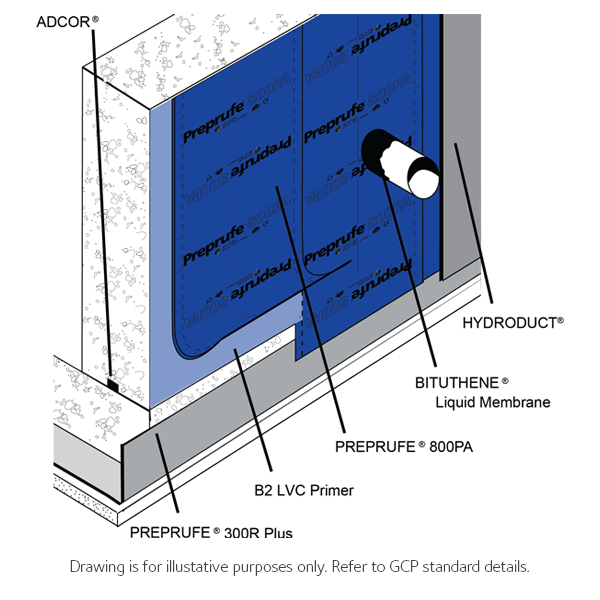

PREPRUFE® 800PA post-applied waterproofing membrane works seamlessly with PREPRUFE® pre-applied membranes to create a complete, fully integrated system for below-grade waterproofing. The self-adhesive waterproofing membrane is composed of a high performing HDPE film for resistance against punctures, and an aggressive, specially formulated fully synthetic, non-asphaltic adhesive.

Product Advantages

- Aggressive Adhesion – Synthetic, non-asphaltic adhesive for aggressive adhesion and peel resistance

- Superior Performance - Tough, high strength, elongation, tear resistant properties

- Fully Bonded - Creates a watertight seal, especially when installed with PREPRUFE® pre-applied membranes, to form a complete, below-grade waterproofing system

- Enhanced Productivity - 4 ft. wide roll for increased worker efficiency & reduced opportunity for water migration with decreased critical entry points

- Quick Application - Improved release liner for quick and easy removal

- Elastomeric - Accommodates movements and bridges concrete shrinkage cracks

- Water and Vapor Barrier - Provides protection for all basements which need to be leak free

- Gas resistant - Contributes to methane, carbon dioxide and radon gas protection

- Sustainable - Made with Red List Free materials – meets the criteria for Living Building Challenge (LBC)

System Components

Membranes

- PREPRUFE® 800PA Membrane for application to surfaces at ambient temperatures of 40°F (5°C) or above

- PREPRUFE® 800PA Low Temperature Membrane for low temperature applications when surface and ambient temperatures are between 25°F (-4 °C) and 60°F (16 °C)

Ancillary Components

(the most current Data Sheets for all system components are available on gcpat.com)

- BITUTHENE® Liquid Membrane – Two component, elastomeric, liquid applied detailing compound

- BITUTHENE® Mastic – Rubberized asphalt-based mastic

- PREPRUFE® Detail Tape - Double sided self-adhesive tape

- HYDRODUCT® - High impact and creep resistant geo-composite and protection layer

Limitations of Use

- Approved uses only include those uses specifically detailed in this Product Data Sheet and other current Product Data Sheets that can be found at gcpat.com. PREPRUFE® 800PA membranes are not intended for any other use. Contact GCP Technical Services where any other use is anticipated or intended.

- PREPRUFE® 800PA membranes are designed where in-service temperatures will not exceed 130 °F (54°C).

Safety and Handling Information

Users must read and understand the product label and Safety Data Sheets (SDS’s) for each system component before use. All users should acquaint themselves with this information prior to working with the material. Carefully read detailed precaution statements on the product labels and SDS’s before use. The most current SDS’s can be obtained from our web site at gcpat.com or by contacting GCP toll free at 1-866-333-3SBM (3726)

Storage

The rolls of PREPRUFE® 800PA membrane are to be transported only in boxes packed upright on shrink-wrapped pallets and must be stored upright on site. The stacking of membrane is not allowed. Before installation, the membrane must be protected from direct sunlight and moisture. Punctual or lineal loading and exposure to solvent vapor shall be avoided.

Installation

Technical Support, Details and Technical Letters

The most up to date detail drawings and technical letters are available at gcpat.com. For complete application instructions, please refer to the current GCP Applied Technologies Contractor Handbook and Literature on (www.gcpat.com). Documents in hardcopy as well as information found on websites other than www.gcpat.com may be out of date or in error.

Before using this product it is important that information be confirmed by accessing www.gcpat.com and reviewing the most recent product information, including without limitation Product Data Sheets and Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations. Please review all materials prior to installation of PREPRUFE® 800PA Membrane. For technical assistance with detailing and problem solving please contact your local GCP Representative.GCP Representatives can be located on www.gcpat.com.

Temperature

- Apply PREPRUFE® 800PA Membrane only in dry weather and when air and surface temperatures are 40°F (5°C) or above.

- Apply BITUTHENE® Adhesive Primer B2 LVC in dry weather above 25°F (-4°C). (See separate product information sheet.)

Surface Preparation

Surfaces should be structurally sound and free of voids, spalled areas, loose aggregate and sharp protrusions. Remove contaminants such as grease, oil and wax from exposed surfaces. Remove dust, dirt, loose stone and debris. Concrete must be properly cured (minimum 7-days for normal structural concrete and 14-days for lightweight structural concrete).

If time is critical, BITUTHENE® Adhesive Primer B2 LVC may be used to allow priming and installation of membrane on damp surfaces or green concrete. Priming may begin in this case as soon as the concrete will maintain structural integrity. Use form release agents which will not transfer to the concrete. Remove forms as soon as possible from below horizontal slabs to prevent entrapment of excess moisture.

Excess moisture may lead to blistering of the membrane. Cure concrete with clear, resin-based curing compounds which do not contain oil, wax or pigment. Except with BITUTHENE® Adhesive Primer B2 LVC, allow concrete to thoroughly dry following rain. Do not apply any products to frozen concrete.

Repair defects such as spalled or poorly consolidated areas. Remove sharp protrusions and form match lines. On masonry surfaces, apply a parge coat to rough concrete block and brick walls or trowel cut mortar joints flush to the face of the concrete blocks.

Priming

- Apply BITUTHENE® Adhesive Primer B2 LVC by a lamb’s wool roller at a coverage rate of 325–425 ft2/gal (7.5–10.0 m2/L). Allow primer to dry one hour or until tack-free.

- Apply BITUTHENE® Primer WP-3000 by spray or roller at a coverage rate of 500–600 ft2/gal (12–15 m2/L). Allow to dry one hour or until concrete returns to original color.

- Dry time may be longer in cold temperatures. Re-prime areas if contaminated by dust. If the work area is dusty, apply membrane as soon as the primer is dry.

- Do not apply any primer onto PREPRUFE® 800PA membrane.

Application on Vertical Surfaces

Apply membrane in lengths up to 8 ft. (2.5 m). Overlap all seams at least 2 in. (50 mm). On higher walls apply membrane in two or more sections with the upper overlapping the lower by at least 2 in. (50 mm). Roll all membrane with a hand roller.

Terminate the membrane at grade level. Press the membrane firmly to the wall with the butt end of a hardwood tool such as a hammer handle or secure into a reglet. Failure to use heavy pressure at terminations can result in a poor seal. A termination bar may be used to ensure a tight seal. Terminate the membrane at the base of the wall if the bottom of the interior floor slab is at least 6 in. (150 mm) above the footing. Otherwise, use appropriate inside corner detail where the wall and footing meet. A 1/8 in. (3 mm) x 1 in. (25 mm) aluminum termination bar aligned with the top of the membrane is recommended for terminations on CMU.

Membrane Repairs

PREPRUFE® 800PA film has an internal grey/black layer. When damage occurs, the grey/black layer is exposed on the white surface. Damaged areas should be repaired with a patch applied to a clean, dry surface extending 6 in. beyond damage in all directions and firmly rolled. Seal all edges of the patch with BITUTHENE® Liquid Membrane.

Drainage

HYDRODUCT® drainage composites and or protection boards are recommended for both active drainage and protection of the membrane. See HYDRODUCT® Product Data Sheet at gcpat.com

Insulation

Always apply PREPRUFE® 800PA membrane directly to primed or conditioned structural substrates. Insulation, if used, must be applied over the membrane. Do not apply PREPRUFE® 800PA membranes over lightweight insulation over concrete.

Protection of Membrane

- Protect PREPRUFE® 800PA membranes to avoid damage from other trades, construction materials or backfill. Place protection immediately in temperatures above 77°F (25°C) to avoid potential for blisters.

- On vertical applications, use HYDRODUCT® 220 Drainage Composite. Adhere HYDRODUCT® 220 Drainage Composite to membrane with PREPRUFE® Detail Tape. Alternative methods of protection are to use 1 in. (25 mm) expanded polystyrene or 1/4 in. (6 mm) extruded polystyrene that has a minimum compressive strength of 8 lbs./in.2 (55 kN/m2). Such alternatives do not provide positive drainage to the system. If 1/4 in. (6 mm) extruded polystyrene protection board is used, backfill should not contain sharp rock or aggregate over 2 in. (50 mm) in diameter. Adhere polystyrene protection board with PREPRUFE ® Detail Tape.

Backfill

Place backfill as soon as possible. Use care during backfill operation to avoid damage to the waterproofing system. Follow generally accepted practices for backfilling and compaction. Backfill should be added and compacted in 6 in. (150 mm) to 12 in. (300 mm) lifts.

Supply

| PREPRUFE® 800PA OR PREPRUFE® 800PA LOW TEMPERATURE | |

|---|---|

| Roll Dimensions (Nominal) | 4 ft. x 115 ft. roll (452 ft2) [1.2 m x 35 m] |

| Roll weight | 77 lbs. (35 kg) gross |

| Palletization | 16 rolls per pallet |

| Storage | Store upright in dry conditions below 86°F (+30°C). |

Ancillary Components (the most current Data Sheets for all system components are available on gcpat.com)

Physical Properties

(PREPRUFE® 800PA & PREPRUFE® 800PA Low Temperature Waterproofing Membranes)

| PROPERTY | TYPICAL VALUE | TEST METHOD |

|---|---|---|

| Color | White | |

| Roll Dimensions | 4 ft. x 115 ft. roll (452 ft2) | |

| Thickness | 30 mils (0.8 mm) nominal | ASTM D3767 — method A |

| Flexibility, 180° bend over 1 in. (25 mm) mandrel at -25°F (-32°C) |

Unaffected | ASTM D1970 |

| Tensile strength, membrane, die C | 1000 psi (8274 kPa) minimum | ASTM D4121 |

| Crack cycling at -25°F (-32°C), 100 cycles | Unaffected | ASTM C836 |

| Lap Sheer Strength | 30 lbs. minimum | ASTM D10022 |

| Peel strength | 16 lbs./in (1927 N/m) | ASTM D9033 |

| Puncture resistance, membrane | 100 lbs. minimum (467 N) | ASTM E154 |

| Resistance to hydrostatic head | >231 ft. (71 m) of water | ASTM D5385 |

| Permeance | <0.1 perms | ASTM E96, section 12—water method |

| Water absorption | 0.1% | ASTM D570 |

2. The test is conducted 15 minutes after the lap is formed and run at a rate of 50 mm (2 in.) per minute @ 40°F (5°C).

3. The 180-peel strength is run at a rate of 12 in. (300mm) per minute.

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

PREPRUFE, BITUTHENE, HYDRODUCT and ADCOR are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-09-16

https://ca.gcpat.com/en/solutions/products/preprufe-800pa-post-applied-waterproofing-membrane/preprufe-800pa-post-applied