PREPRUFE® SCS

Blindside waterproofing system for shotcrete foundation walls

Product Description

PREPRUFE® SCS is a unique blindside waterproofing system specifically developed to provide a high performance waterproofing solution for shotcrete foundation walls. The waterproofing system consists of the following:

- PREPRUFE® SCS membrane consisting of a polymer mesh-reinforced cavity backed by a plastic film facing the soil retention system, and faced with a non-woven, semi-permeable geotextile acting as a shotcrete barrier while allowing grout to bond to the shotcrete

- PREPRUFE® SCS grout injection ports installed prior to shotcrete placement to facilitate hydrophilic grout injection

- PREPRUFE® SCS hydrophilic grout post-injected under pressure into composite sheet through injection ports left protruding through the shotcrete. The shotcrete side of the membrane enables grout to bond with shotcrete across the permeable geotextile.

The PREPRUFE® SCS composite sheet membrane is applied vertically to timber lagging or other soil retention systems. Shotcrete is then placed directly against the geotextile side of the membrane. Unlike conventional waterproofing systems, the PREPRUFE® SCS waterproofing system has injection ports to facilitate grout injection into a pre-created cavity space, forming an in-situ monolithic grout membrane with uniform thickness.

After shotcrete placement, injection of the specially formulated PREPRUFE® SCS hydrophilic grout is used to fill and seal the system, providing ultimate waterproofing protection. All components of the specially developed PREPRUFE® SCS system work together to form a continuous and integral bond to the structure, eliminating lateral water migration between the membrane and the shotcrete. When properly installed and grouted, the PREPRUFE® SCS system will protect against water ingress.

Product Advantages

- Durable system designed specifically to withstand the force of shotcrete placement

- Post-injected grout fills and seals, providing ultimate waterproofing protection

- Aggressive bond to shotcrete resists lateral water migration

- Excellent resistance to hydrostatic pressure

Installation

The PREPRUFE® SCS system is intended to be installed by GCP trained applicators only. For a list of trained applicators, please contact your GCP representative. All PREPRUFE® SCS system materials shall be supplied by GCP Applied Technologies and applied strictly in accordance with the company’s instructions. Refer to the PREPRUFE® SCS waterproofing systems installation manual for detailed application instructions.

Substrate Preparation

It is essential to create a sound and solid substrate to eliminate movement during the shotcrete placement. Substrates must be regular and smooth with no gaps or voids greater than 1/2 in. (12 mm). Grout around all penetrations such as utility conduits for stability.

If necessary, apply plywood, rigid insulation, HYDRODUCT® 220 drainage composite or other approved facing to the substrate to provide support to the membrane. Board systems such as timber lagging must be close butted to provide support and not more than 1/2 in. (12 mm) out of alignment. For areas close to finished grade where steel soldier piles and wood lagging will be removed, install a protection layer of 1/2 in. (12 mm) thick cementitious wall board centered over the steel soldier piles.

Apply the PREPRUFE® 300R membrane below all horizontal slabs and rafts (i.e., mud slabs), extending a minimum of 18 in. (457 mm) beyond the top of the slab and protect from over splash. Refer to the PREPRUFE® 300R membrane product information for more detailed installation instructions. If the PREPRUFE® 300R membrane will not be used below the slab, consult your GCP representative.

Membrane Installation

The PREPRUFE® SCS membrane can be applied at temperatures of 25°F (-4°C) or above. The waterproofing membrane may be installed in any convenient length, but is best installed vertically along the full length of the soil retention. With the geotextile side facing toward the shotcrete placement, attach the membrane to the substrate with staples, approved by GCP, spaced at 24 to 36 in. (610 to 914 mm) O.C. down the middle of the membrane. Ensure the plastic film extension and the underside of the succeeding sheet are clean, dry and free from contamination before attempting to overlap. Apply PREPRUFE® Detail Tape at the center of the film extension. Overlap the seams by a minimum of 2 1/2 in. (64 mm) with membrane and ensure the top piece of membrane has only the geotextile extension (not plastic film) on the top of the existing membrane. Remove the release liner from the PREPRUFE® Detail Tape and roll the membrane firmly at the seam with a hand roller to ensure a good seal. Mechanically fasten the seam on the geotextile overlap with staples spaced at 12 to 18 in. (305 to 457mm) O.C.

For roll ends and cut edges, place PREPRUFE® CJ Tape under the membrane with the adhesive side facing membrane centered along the ends/cut edges. Secure strips to the substrate with staples. Ensure the underside of the membrane is clean, dry and free from contamination. Butt joint the membrane and roll firmly at the seam with a hand roller to ensure a good seal. Apply PREPRUFE® SCS geotextile strip centered over the butt joint and secure on the top and bottom of the butt joint with staples at 12 to 18 in. (305 to 457 mm) O.C.

Penetrations

Follow these steps to seal around penetrations such as service pipes, rebar, all-thread and metal dowels:

- Clean loose dust or dirt from the penetration and the surrounding substrate surface using a clean, dry cloth or brush. Remove rust, if applicable, with a wire brush and wipe clean.

- Cut the PREPRUFE® SCS membrane tight to within 1/2 in. (12 mm) of the penetration. If the membrane is 1 in. (25 mm) or more from the penetration, install a cut-to fit “filler strip” of the membrane to cover the gap, following the membrane repair guidelines until the membrane is within 1/2 in. (12 mm) of the penetration.

- Apply SWELLSEAL® WA to cover the gap and form a minimum of 1/4 in. (6 mm) but no more than 1 in. (25 mm)-thick continuous fillet between the plastic film side of the membrane and the base of the penetration. Extend a 90 mil (2.2 mm) continuous coating of sealant onto the surface of the membrane, overlapping a minimum of 1 in. (25 mm).

Tiebacks

Prior to membrane installation, fasten the PREPRUFE® Tieback Cover ABS base to the substrate to cover the tieback. Apply PREPRUFE® Detail Tape around the outside edge of the ABS base. Install the PREPRUFE® SCS membrane over the ABS base and then cut out the membrane 1/2 in. to 1 in. (12 mm to 25 mm) around the dome hemisphere. Remove the release paper on the PREPRUFE® Detail Tape and press the membrane firmly to the ABS base. Roll the membrane firmly at the joint with a hand roller to ensure a good seal. Position the PREPRUFE® Tieback Cover on top of the ABS base and mechanically fasten the PREPRUFE® dome. Apply PREPRUFE® Detail Tape (LT or HC) over the top edge of the tieback cover.

Terminations

Position PREPRUFE® CJ Tape under the membrane along the termination, centered along the membrane cut edges/roll ends. Secure half of the tape under the membrane to the substrate with staples. Press the membrane firmly onto the tape and fold over the membrane. Roll the folding area with a hand roller to ensure a good seal. Remove the release paper. Mechanically fasten with staples at 12 in. (305 mm) O.C. along the top edge of the PREPRUFE® CJ Tape.

Tie-ins of PREPRUFE® SCS Membrane to PREPRUFE® 300R Sub-slab Waterproofing

Install the PREPRUFE® 300R membrane over the prepared substrate as detailed in the PREPRUFE® 300R membrane installation guide. If the PREPRUFE® 300R membrane will not be used below the slab, consult your GCP representative.

Apply two parallel lengths of PREPRUFE® Detail Tape, one at the top edge of the PREPRUFE® 300R membrane and the other 6-12 in. (150-300 mm) from the top of slab. Remove the release liner. Press the PREPRUFE® SCS membrane to the tape and roll firmly with a hand roller. If necessary, apply 4 in. (102 mm) pieces of PREPRUFE® Detail Tape at 4 ft (1.2 m) O.C. to the bottom edge of the PREPRUFE® SCS membrane to secure it to the PREPRUFE® 300R membrane. Do not use mechanical fasteners through the PREPRUFE® 300R membrane.

Membrane Repair

Inspect the membrane before and after installation of reinforcement steel. Repair damage by wiping the area with a damp cloth to ensure the area is clean and free from dust, and allow to dry. Repair small punctures (1/2 in./12 mm or less) and slices by applying SWELLSEAL® WA centered over the damaged area. Repair large holes and punctures by first cutting out the damaged area. Next, prepare a length of PREPRUFE® CJ Tape at least 3 in. (76 mm) wider than the damaged area on each side. If necessary, overlap the PREPRUFE® CJ Tape with a 3 in. (76 mm) overlap to make a large piece. Center the PREPRUFE® CJ Tape under the damaged area with the adhesive side facing the membrane. Secure the tape with staples. Ensure the membrane overlaps at least 3 in. (76 mm) on the tape on each side. Apply a patch of membrane with the plastic film removed and the geotextile side facing shotcrete extended 6 in. (150 mm) beyond the damaged area. Secure the patch with staples at 4 in. (100 mm) O.C. on each side.

Injection Port Installation

Install the injection port assembly after installation of reinforcement steel and before shotcrete placement. Pre-assemble the injection port assembly by cutting a piece of PREPRUFE® SCS injection tube 4 in. (100 mm) longer than the thickness of the wall and twisting the tube into a PREPRUFE® SCS injection base until a tight connection is made.

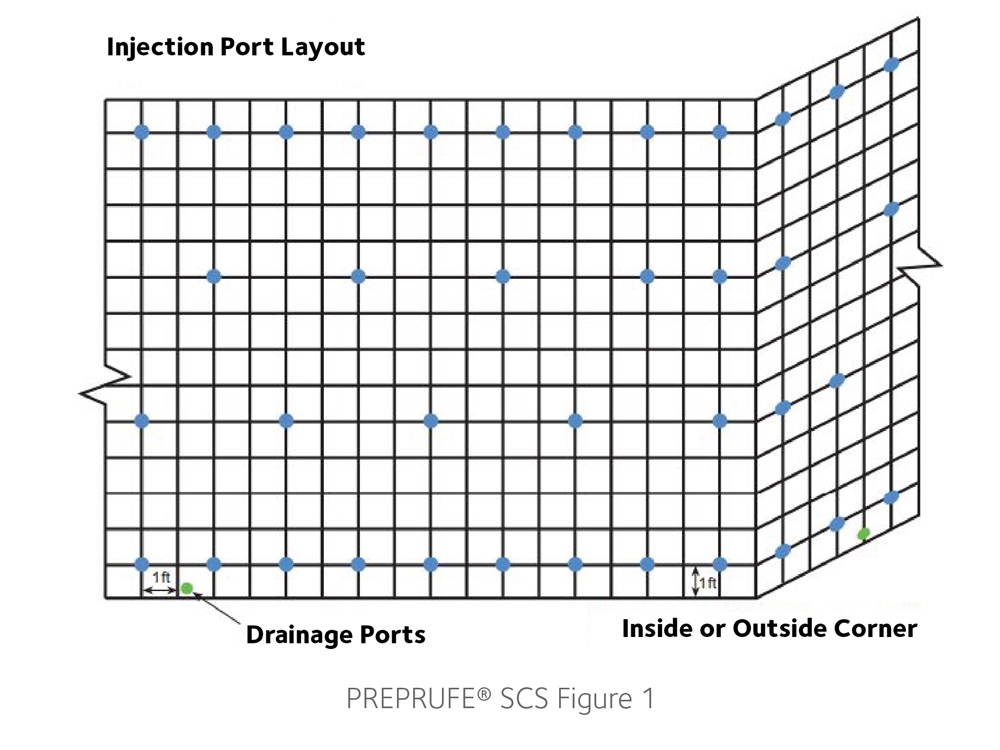

The injection port assembly spacing shall be 4 feet in any direction with 2 feet offset every vertical step. The top and bottom layer of injection port assemblies shall be two feet in spacing, located one foot from the edge of the membrane. All vertical corners and terminations shall have port assemblies spaced 2 feet vertically, located one foot from the corner or termination. To allow existing water to drain from the system prior to grout injection, install additional port assemblies 1 in. (25 mm) above the bottom of the membrane at 20 feet (6.1 m) O.C. (refer to Figure 1). All tie-back covers shall have one injection port assembly installed, located on the membrane directly above the tieback (not shown in the figure).

Position the injection port assembly adjacent to the intersection of the reinforcing steel. Press the injection port assembly tightly against the membrane and screw the injection base into the membrane by turning the nozzle clockwise. The port assembly should be twisted until it cannot turn any further (usually 1/4 - 1/2 rotation, although more may be needed). If the port assembly does not snag the geotextile or stop rotating, it has not been attached to the membrane properly. Repeat with a new injection base. Tie the tubing to both the inside and outside layer of reinforcing steel with rebar ties. Cover the tubing end with duct tape to prevent blockage during the shotcrete placement.

Shotcrete Placement

Inspect the port installation before the placement of shotcrete to ensure all ports are still attached to the membrane. Reinstall any damaged or loose ports.

It is recommended that shotcrete be placed within 56 days (42 days in hot climates) of the membrane installation. Shotcrete must be placed in accordance with ACI 506.2. Never use a sharp object to consolidate the concrete. Avoid putting large force on the injection tubing during shotcrete surface finishing. Shotcrete surface finish around all injection ports should be the same as the rest of the wall, avoiding any rough areas or projections adjacent to the ports.

Grouting Procedure

Safety

Read the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office, by calling GCP toll free at 1-866-333-3SBM (3726) and in some cases from our website at gcpat.com.

Users must be made aware that the equipment used for the PREPRUFE® SCS waterproofing system operates under pressure. Only trained individuals should operate this equipment. Installation personnel should utilize all necessary personal protective gear.

General Guidelines

PREPRUFE® SCS hydrophilic grout can be injected into the PREPRUFE® SCS membrane a minimum of seven days to a maximum of six months after the shotcrete placement. This minimum wait period allows the shotcrete to gain sufficient compressive strength. A minimum concrete compressive strength of 1,500 psi (10 N/mm2) is recommended prior to grout injection.

Port Preparation

Cut the tubing flush to the shotcrete surface and install the PREPRUFE® SCS injection packer into the tubing. Allow all water to gravity drain from the bottom “drainage ports” prior to installing the packer. Tighten packers using a ratchet or open-end wrench, by turning clockwise until firm and secure. Packers are supplied with a one-way check valve to minimize back flow during the injection procedure.

Grout Injection

The pump mix manifold and clutch that will be used for injecting PREPRUFE® SCS hydrophilic grout should be flushed with flushing agent prior to beginning the grout operation. Flushing lubricates the system. After injecting, the pump mix manifold and clutch should be flushed to remove any liquid grout residue. The general injection technique is as follows:

- Measure the material’s temperature and refer to the chart in the detailed installation manual for usage of Activators A and B to get 60–90 seconds setting time. All results are based on laboratory tests. Site trials should always be carried out to determine the actual setting time.

- Determine the pumping volume per port as outlined in the detailed installation manual.

- Begin injection from bottom to top. Start injection from one end to the other end or any convenient distance at each horizontal level, then switch to the next level and follow the same sequence.

- If the pump sits idle (no grout being injected) for more than 30 seconds, flush the pump mix manifold and clutch with flushing agent.

If excessive pumping pressures are needed to cause grout flow or manifold pressure changes significantly, discontinue injection, flush the pump mix manifold and clutch and notify your GCP representative immediately. Avoid sudden application of high pressures during the injection process. Grouting pressure before the mixing head shall not exceed 500 psi.

Environmental Conditions

Precautions

A GCP representative should be consulted prior to application to verify that site conditions are appropriate for the PREPRUFE® SCS system.

The PREPRUFE® SCS system includes injection of grout at high pressures. The project structural engineer should evaluate the site for potential effects on adjacent building elements. Injection has the potential to cause hidden damage if installed incorrectly.

Limitations

Low temperatures will significantly extend set times. Bring the product up to a minimum temperature of 50°F for a minimum period of 24 hours prior to use. If site temperatures are extremely low, material should be held in a warm area before and during use to maintain the product’s temperature. Allow no water into open containers. DO NOT EXCEED 90 ºF WHEN WARMING. (CAUTION—pH NOTICE. Water used on site to activate grouts must be in a range of pH 5.5–7 for optimum grout quality. Varying water pH will cause the reaction times to change. Test ground water for pH and consult with GCP to ensure the pH falls within the threshold limitations.)

Storage & Handling

All PREPRUFE® SCS waterproofing system grout components should be shipped and stored in cool, dry, protected conditions at temperatures between 40°F and 77°F, out of direct sunlight and in accordance with the relevant site health & safety regulations. Do not thin with solvents. Warning: Do not combine components other than mixing during field application, as this may cause an exothermic reaction with the production of intense heat, smoke and irritating fumes.

Store in unopened containers. Shelf life in these conditions is 6 months from date of manufacture.

Physical Properties

| Property | Typical Value | Test Method |

|---|---|---|

| Thickness | 0.17 in. | ASTM D6525 |

| Elongation at ultimate break | 200% | ASTM E154 |

| Tensile strength | 300 psi | ASTM E154 |

| Peel adhesion to concrete | 5 pli | ASTM D903 |

| Resistance to hydrostatic head | 200 ft (60 m) | ASTM D53851 |

| Puncture resistance | 200 lbs (890 N) | ASTM E154 |

| Impact resistance, membrane | No change in appearance | SAE J4002 |

Footnotes:

1. Hydrostatic head tests are performed by casting concrete against the geotextile side of membrane with a lap then injecting grout into membrane space. The cured block is cracked and then placed in a chamber where water is introduced to the membrane surface including the lap up to 231 ft (70 m) head.

2. The tests are performed by projecting 3/8 in. gravel by means of 100 psi air blast onto geotextile side of membrane.

Supply of Components

Membrane Installation

| Product Name | Description | Supply |

|---|---|---|

| PREPRUFE® SCS Membrane | A unique composite sheet membrane applied vertically to the soil retention system serving as a channel to contain the flow of the post-injected grout. | Rolls, 40 in. (1 m) x 100 ft, with a lap extension on both sides to provide continuous membrane between rolls |

| PREPRUFE® Detail Tape | A two-sided, highly aggressive adhesive tape for sealing side laps and other miscellaneous details. | Rolls, 2 in. x 50 ft, 18 rolls per box |

| PREPRUFE® SCS Geotextile Strip | A semi-permeable geotextile for covering cut edges and roll ends | Rolls, 12 in. x 1000 ft, 1 roll per box |

| PREPRUFE® CJ Tape (LT or HC)* | A reinforced pressure sensitive tape for sealing cut edges, roll ends, and terminations. | Rolls, 8 in. x 49 ft, 4 rolls per box |

| SWELLSEAL® WA | A caulk-applied hydro-swelling mastic for sealing around pipe penetrations, rebar, utility conduits, etc. | 10.5 oz cartridges, 12 per box |

| PREPRUFE® 300R | A composite sheet membrane for transitions to other GCP waterproofing systems (top, bottom, sides). | Refer to GCP PREPRUFE® 300R data sheet |

Injection Port Assembly Installation

| Product Name | Description | Supply |

|---|---|---|

| PREPRUFE® SCS Injection Base | A specially designed component used to mechanically attach the injection tube to the membrane. | 1000 bases per box |

| PREPRUFE® SCS Injection Tube | A durable, flexible tube used to deliver the grout to the membrane after shotcrete placement. | 100 lf coils, 5 coils per box |

Grout Injection

| Product Name | Description | Supply |

|---|---|---|

| PREPRUFE® SCS Injection Packer | Button-head, backflow prevention packer used to connect the grout pump to the injection tube. | 500 packers per box |

| PREPRUFE® SCS Hydrophilic Grout Part A | Grout part A for injection into PREPRUFE® SCS Membrane providing ultimate waterproofing protection. | 5 gallon pails |

| PREPRUFE® SCS Hydrophilic Grout Part A Activator | Activator used for Part A to provide for temperature flexibility during installation. | 28 fl oz cans |

| PREPRUFE® SCS Hydrophilic Grout Part B | Grout part B for injection into PREPRUFE® SCS Membrane providing ultimate waterproofing protection. | 50 gallon drums or 5 gallon pails |

| PREPRUFE® SCS Hydrophilic Grout Part B Activator** | Activator used for Part B to provide for temperature flexibility during installation. | 2 lb jars |

Ancillary Products (if required)

| Product Name | Description | Supply |

|---|---|---|

| PREPRUFE® Tieback Cover | A specially designed, two-part cover used to maintain waterproofing integrity at soil retention tieback heads. | Refer to GCP PREPRUFE® Tieback Cover data sheet |

| PREPRUFE® Tape (LT or HC)* | A reinforced pressure sensitive tape for sealing PREPRUFE® Tieback Cover. | Rolls, 4 in. x 49 ft, 4 rolls per box |

| HYDRODUCT® 220 Drainage Composite | A prefabricated geocomposite drain for use as a combined drainage and protection layer. | Refer to GCP HYDRODUCT® 220 data sheet |

* LT denotes Low Temperature (between 25°F (-4°C) and 86°F (+30°C)); HC denotes Hot Climate (50°F (>+10°C))

** Part B Activator is shipped as hazmat: corrosive

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

PREPRUFE is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-09-16

https://ca.gcpat.com/en/solutions/products/preprufe-comprehensive-waterproofing-system/preprufe-scs