PERM-A-BARRIER® VPL 50RS UV STABLE Membrane

UV stable, Spray-friendly, Early wash-off resistance, vapor permeable

Product Description

GCP (GCP) PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is a fluid applied, one component, STPE (Silyl Terminated Polyether) vapor permeable air and water barrier. When applied to approved construction surfaces, PERM-A-BARRIER® VPL 50RS UV STABLE is designed to cure and form a resilient, monolithic, fully bonded elastomeric membrane, and to create a continuous barrier against air infiltration and exfiltration, reducing associated energy loss and condensation problems.

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is specifically designed to provide superior protection against the damaging effects of air and liquid water ingress on the building envelope. Vapor permeability allows the wall to breathe and dry, minimizing the risk of water vapor from being trapped and condensing within the wall. While PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is vapor permeable, it is impermeable to liquid water, allowing the material to act as a water drainage plane within the wall.

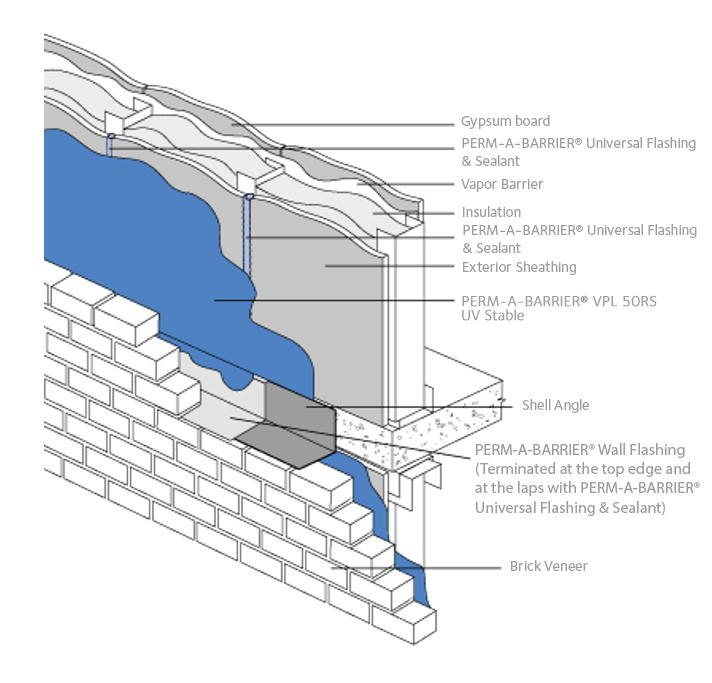

Typical Vapor Permeable Air Barrier Membrane Application. Drawings are for illustration purposes only. Refer to gcpat.com for specific application details.

Product Advantages

- Permanently UV stable behind maximum 1 in.(25 mm) wide open joint rainscreen system; provides design flexibility

- Can be exposed for up to 12 months during construction

- Early wash-off resistance

- Can be applied to damp-to-touch surfaces that are free of liquid water

- Sprayer friendly formula requiring light spray equipment

- Can be spray-, roller- or brush-applied

- Fire resistant – meets NFPA 285 as part of various wall assemblies with and without foam plastic insulation

- VOC Content, 32 g/L (calculated)

- Formulated without phthalates and halogens

- Designed to protect against air passage and associated energy losses - meets ASTM E2357 standard

- Vapor permeable. Minimizes moisture from being permanently trapped in the wall cavity by allowing the wall’s ability to “breathe” and dry

- Single component. Fast and easy application with simple roller or spray equipment

- Fully bonded - transmits wind loads directly to the substrate, and prevents water migration between the barrier and substrate

- Seamless continuous membrane integrity with no laps

- Adheres to properly prepared clean common construction substrates such as wood, block, concrete, OSB, and gypsum sheathing

- Can be used to treat sheathing joint less than 1/8 in.

System Components

MEMBRANE

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane

Ancillary Products

- PERM-A-BARRIER® Universal Flashing & Sealant.- one part moisture curing, sealant for detailing and joint treatments

- PERM-A-BARRIER® Wall Flashing – heavy-duty fully adhered membrane for through-wall flashing detailing. All Wall Flashing must be applied prior to the application of PERM-A-BARRIER® VPL 50RS UV STABLE. The top and side edges of all laps, seams, repairs, as well as cuts, punctures, and other damage must be sealed with a PERM-A-BARRIER® Universal Flashing & Sealant. See PERM-A-BARRIER® Wall Flashing Product Data Sheet at gcpat.com for details

- PERM-A-BARRIER® NPS Detail Membrane – primer-less flexible membrane for detail flashing areas. Must be applied prior to PERM-A-BARRIER® VPL 50RS UV STABLE membrane and terminated on the edges with a bead of PERM-A-BARRIER®

- PERM-A-BARRIER® Detail Membrane – flexible, fully adhered membrane for detail flashing areas. Must be applied prior to PERM-A-BARRIER® VPL 50RS UV STABLE Membrane and terminated on the edges with a bead of PERM-A-BARRIER® Universal Flashing & Sealant.

- PERM-A-BARRIER® Aluminum Flashing – flexible, aluminum faced, fully adhered membrane for detail flashing areas must be applied prior to PERM-A-BARRIER® VPL 50RS UV STABLE membrane and terminated on the edges with a bead of PERM-A-BARRIER®

- PERM-A-BARRIER® Ultra – heavy duty fully adhered flashing. PERM-A-BARRIER® Ultra is a 30mil thick cold applied self-adhered membrane/flashing with cross laminated high density polyethylene film laminated to an aluminum foil and coated on high temperature 100% Butyl rubber adhesive. PERM-A-BARRIER® Ultra can be wet set (1 hr after application) into PERM-A-BARRIER® VPL 50RS UV Stable. Alternatively, PERM-A-BARRIER® Ultra can be applied over cured PERM-A-BARRIER® VPL 50RS UV Stable (24 hrs after application).

Limitations of use

- Approved uses only include those specifically detailed in this Product Data Sheet and other current Product Data Sheets that can be found at gcpat.com. For any other anticipated use contact GCP Technical Services.

- Do not install during precipitation (rain, snow, sleet, etc.) events.

- PERM-A-BARRIER® VPL 50RS UV STABLE Membrane has a maximum in-service temperature of 300° F (148°C).

- PERM-A-BARRIER® VPL 50RS UV STABLE Membrane should not be used in waterproofing applications in hydrostatic conditions.

- If, or when, transitioning PERM-A-BARRIER® VPL 50RS UV STABLE Membrane to PERM-A-BARRIER® VPS 30 Membranes, please consult GCP Technical Service on proper transition.

- PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is not compatible with petroleum solvents, fuels and oils, materials containing creosote, pentachlorophenol, or linseed oil.

Safety and Handling Information

Read and understand the product label and Safety Data Sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office, by calling GCP toll free at 1-866-333-3SBM (3726), and in some cases from our website at gcpat.com.

Storage

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane should be stored under cover in original sealed containers above 50°F (10°C) and below 90°F (32°C). The shelf life is eighteen (18) months in unopened containers. For temporary storage, store opened containers with plastic protective liner covering the material and lid tightly closed to prevent moisture exposure. PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is moisture-curing and should not be mixed with water during application.

Installation

Technical Support, Details, and Technical Letters

The most up to date detail drawings and technical letters are available at gcpat.com. Documents in hardcopy as well as information found on websites other than, gcpat.com, may be out of date or in error. Before using this product it is important that information be confirmed by accessing gcpat.com and reviewing the most recent product information, including without limitation Product Data Sheets, Contractor Manuals, Technical Bulletins, Detail Drawings, and detailing recommendations. For technical assistance with detailing and problem solving, please contact your local GCP Representative or call toll-free at (866) 333-3SBM (3726) to get contact information for your local GCP Representative.

Surface Preparation

All surfaces must be sound and free from spalled areas, loose aggregate, loose nails or screws, sharp protrusions, or other matter that will hinder the adhesion or regularity of the membrane installation. The surface must also be free from frost, dirt, grease, oil, or other contaminants. Clean loose dust and dirt from the surface by brushing or wiping with a clean, dry cloth.

Application

Membrane Application

PERM-A-BARRIER® VPL 50RS UV STABLE membrane can be installed by spray application as a single continuous, monolithic coat. Prevent from sags, run, or voids by regularly checking wet mil thickness throughout application to assure adequate coverage. The product may also be applied by roller or brush. If applying the membrane by roller or brush, multiple material passes may be necessary to ensure that the required wet thickness is achieved. Contact GCP for further details of local applicators, application techniques and spray equipment.

Application Temperature

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane may be applied at temperatures as low as 10°F (-12°C). During cold weather installation less than 32°F (0°C), product must be stored above 50°F (10°C) for a minimum of 24 hours prior to application to improve spraying and overall product installation.

Thickness Control

Thickness can be controlled by marking the area and spot-checking the thickness with a wet film thickness gauge. Swipe marks on the surface of the PERM-A-BARRIER® VPL 50RS UV STABLE Membrane are acceptable provided the minimum thickness of 20-mils is maintained.

Coverage Rates

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is typically applied at a minimum thickness of 20 mils wet and dry. The theoretical coverage rate (not including waste) at a thickness of 20 mils is approximately 80 ft.2/gal.

Coverage may vary depending on application technique and may be reduced over rough and uneven substrates. The applicator goal should be a continuous membrane at a thickness of 20 mils. Adjust coverage rate accordingly.

Drying

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is dry to touch and can be over coated within 4-hours at 50% R.H, 68°F. The product fully cures in 24-hours. Drying and skinning times may vary depending on temperature, humidity, and surface conditions.

Concrete and Other Monolithic Cementitious Surfaces

Surface irregularities greater than 1/4 in. (6 mm) across and/or 1/8 in. (3 mm) in depth should be filled with a lean mortar mix or non-shrinking grout. Remove concrete form lines and any high spots greater than 1/8 in. (3 mm) in height to ensure uniform surface. On highly dusty or porous substrates it may be necessary to apply a scratch coat of PERM-A-BARRIER® VPL 50RS UV STABLE Membrane prior to rolling or spraying to full thickness. Remove any visible water prior to application.

Concrete Masonry Units (CMU)

The CMU surface should be smooth and free from projections. Strike all mortar joints full and flush to the face of the concrete block. Fill all voids and holes, particularly at the mortar joints, with a lean mortar mix or no shrinking grout. Alternatively, a parge coat (typically one part cement to three parts sand) may be used over the entire surface.

Exterior Sheathing Panels

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane may be applied directly to exterior sheathing panels such as exterior drywall, plywood, oriented strand board (OSB), and glass faced wallboards. To avoid deflection at the panel joints, fasten corners and edges with appropriate screws. Fasteners should be driven flush with the panel surface (not counter sunk) and into the framing system in accordance with the manufacturer’s recommendations. Completely fill the sheathing joint with PERM-A-BARRIER® VPL 50RS UV STABLE or PERM-A-BARRIER® Universal Flashing & Sealant and then install a scratch coat (approx. 15-30 mils) of PERM-A-BARRIER® VPL 50RS UV STABLE or PERM-A-BARRIER® Universal Flashing & Sealant with a margin trowel or similar onto the face of the sheathing approximately 1 in. (25 mm) on each side of the sheathing joint, ensuring the edges are tapered to prevent shadowing of the spray application. When using PERM-A-BARRIER® Universal Flashing & Sealant, once the Sealant is tack free, the PERM-A-BARRIER® VPL 50RS UV STABLE Membrane may be applied. PERM-A-BARRIER® VPL 50RS UV STABLE Liquid Membrane can be used to treat sheathing joint less than 1/8 in.

Detailing

Detailing should be completed prior to applying PERM-A-BARRIER® VPL 50RS UV STABLE Membrane. The field application should completely cover the detail areas to provide a continuous membrane. For a complete description and instructions on individual details, see detail drawings at gcpat.com.

Transitions to beams, columns, windows, and doorframes, etc., can be made with a strip of PERM-A- BARRIER® NPS, PERM-A-BARRIER® Detail Membrane, PERM-A-BARRIER® Aluminum Flashing, PERM-A- BARRIER® Wall Flashing, or PERM-A-BARRIER® Ultra Flashing prior to installing PERM-A-BARRIER® VPL 50RS UV STABLE Membrane. The top edges of all detail Membranes and flashings must be terminated with PERM-A-BARRIER® Universal Flashing & Sealant. All self-adhered membranes, including tapes, must be applied prior to the application PERM-A-BARRIER® VPL 50RS UV STABLE Membrane. Only PERM-A-BARRIER® Wall Flashing membrane can be used for through wall flashing applications or under masonry units.

A minimum 6 in. (150 mm) wide strip of PERM-A-BARRIER® NPS Detail Membrane, PERM-A-BARRIER® Aluminum Flashing, PERM-A-BARRIER® Wall Flashing, or PERM-A-BARRIER® Ultra Flashing should be installed and centered over all outside corners ensuring that all horizontal laps shed water and terminated on the edges with a bead of PERM-A-BARRIER® Universal Flashing & Sealant. Installation of the self-adhered flashing at corners should be installed prior to the PERM-A-BARRIER® VPL 50RS UV STABLE application in accordance with the applicable data sheet and installation instructions. Avoid installing PERM-A-BARRIER® VPL 50RS UV STABLE and PERM-A-BARRIER® Universal Flashing & Sealant under self-adhered flashing. Best practice would be to install corner flashing prior to detailing exterior sheathing joints with PERM-A-BARRIER® VPL 50RS UV STABLE or PERM-A-BARRIER® Universal Flashing & Sealant. Any gaps around penetrations should be grouted solid or filled with a PERM-A-BARRIER® VPL 50RS UV STABLE or PERM-A-BARRIER® Universal Flashing & Sealant prior to the PERM-A-BARRIER® VPL 50RS UV STABLE Membrane application. Refer to standard penetration details.

Cold Weather Application

PERM-A-BARRIER® VPL50RS UV Stable can be applied if the ambient temp is 10° F(-12° C) and rising. It is recommended to store PERM-A-BARRIER® VPL50RS at 50° F(10° C) for a minimum of 24 hours prior to and during installation. This can be maintained during the spray application using 5 gallon pail blanket heaters. When the installation of PERM-A-BARRIER® VPL 50 RS UV Stable is expected to be below 50° F(10° C) a high pressure pump with a minimum of 4000 psi (275.79 bar, 220 volt) is recommended. If a low pressure pump is being used (2500psi/172 bar, 110 volt) it is recommended to keep the material consistently above 50° F(10° C) for a smooth spraying experience. This can be achieved by ensuring the hose is insulated and/or heated while spraying. Hose length should not exceed 50’ in length and a minimum 3/8’ diameter with a 3’ 1/4“whip hose. If poor spray pattern (Fingering - finger spray pattern) is observed increase hose diameter to ½’ and whip hose diameter to 3/8’. For any questions, please contact your local GCP Technical Service Representative.

Application of Insulation and Finishes

PERM-A-BARRIER® VPL 50RS UV STABLE Membrane is not suitable for permanent exposure, except behind open joint rain screen systems with maximum 1 in. (25 mm) joints.. Insulation boards may be installed after the product has fully cured. If the insulation or exterior finish cannot be applied within 12 months of the product application, some form of temporary protection (such as tarpaulins) must be used to protect the product from the effects of sunlight. Installation of insulation boards can be accomplished by using compatible mechanical fasteners.

Cleaning

Tools and equipment are most effectively cleaned using mineral spirits and removing material as soon as possible to prevent moisture curing on tools and equipment. The product should not be left in spray guns, hoses, or pumps for a prolonged period of time unless equipment allows for moisture lock hoses or fittings. For long-term storage, thoroughly flush the entire system with mineral spirits. Do not flush pump with water, and do not cross contaminate with water based materials. Good preventative maintenance will lengthen the life of the pumps.

Supply

| UNIT OF SALE | APPROXIMATE COVERAGE WEIGHT | PALLETIZATION |

| PERM-A-BARRIER® VPL 50RS UV STABLE 1 pail | 80 SF / gallon (400 SF per pail - 5 gallon pail) | 32 pails per pallet |

| PERM-A-BARRIER® VPL 50RS UV STABLE 1 drum | 80 SF / gallon (4,000 SF per drum - 50 gallon drum) | 4 drums per pallet |

Ancillary Products

Supply information for ancillary products can be found at gcpat.com

Physical Properties

| TYPICAL VALUE | TEST METHOD | |

| Color | Black | |

| Solids content by volume | 98.2% | |

| Maximum In-Service Temperature | 300° F (148°C) | |

| Maximum UV Exposure | UV stable behind open-joint rainscreen system; can be exposed up to 12 months during construction | |

| The Volatile Organic Compound | 32 g/L | Calculated |

| Drying time @ 50% R.H., 68°F1 | Complete cure in 24 hours, Skin over in 2 hours | |

| Water resistance of in-place membrane | Pass at >15 psf | ASTM E331 |

| Air permeance | <0.02 L/s∙m2 @ 75 Pa (<0.004 cfm/ft2 @ 1.57 psf) | ASTM E2178 |

| Air leakage | <0.02 L/s∙m2 @ 75 Pa (<0.004 cfm/ft2 @ 1.57 psf) | ASTM E2357 |

| Water vapor transmission | 13 perms @ 20 mils | ASTM E96 - Method B |

| Pull adhesion to glass-mat faced gypsum sheathing2 | >30 psi, facer failure | ASTM D4541 |

| Pull adhesion to CMU | >50 psi | ASTM D4541 |

| Elongation | >250% | ASTM D412—Die C |

| Nail sealability | Pass | ASTM D1970 |

| Low temperature flexibility | Pass at -40 °F | ASTM D1970 |

| Wall assembly fire test | Pass as part of various wall assemblies with foam plastic insulation | NFPA 285 |

| Crack Bridging | Pass | ASTM C1305 for 1/8 inch crack at -20°F (-28.9°C) |

| Mold, Mildew and Fungal growth | Pass | ASTM D 5590-17 |

Footnote:

- Drying and skinning times may vary depending on temperature, humidity and surface conditions

- Failure occurs when glass facing pulls away from gypsum core

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

PERM-A-BARRIER is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© 2021 GCP Applied Technologies Inc. All rights reserved

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-09-16

https://ca.gcpat.com/en/solutions/products/perm-a-barrier-air-barrier-system/perm-a-barrier-vpl-50rs-uv-stable-membrane