Manufacturing facility expansion

From detergent to floor cleaner, from shampoo to prescription drugs, household products need packaging. When one of the world’s leaders in plastic container manufacturing needed to expand into Central Louisiana to serve one of their key customers, it meant the construction of a new manufacturing facility.

The design of the building was important, and special consideration was directed at the performance of the floor needed to support the heavy manufacturing equipment.

Constructing a strong concrete floor

The project initially specified steel fibers in the slab-on-ground concrete flooring of the plant. Steel fibers have been used in these applications for years. However, when Kevin Williams, TXI's Area Manager, was asked to supply concrete for the project, he knew there was an even better way to construct the manufacturing facility floor.

While the company had taken steps already to design slabs using macro fibers, eliminating welded wire mesh from their projects, steel fibers still posed disbursement and finishing problems for them. With the requirement of high, long-term performance at a cost-effective price, Kevin recommended STRUX® synthetic macro fibers to replace the steel fibers.

In fact, for this project, STRUX® 90/40 provided an opportunity for better performance, which immediately prompted Imperial Concrete, the concrete contractor on the project, to take the quote to the owner.

Smooth finish for a quality floor

The owners of the manufacturing facility were quick to embrace the switch to STRUX®, acknowledging the advantages synthetic macro fibers have over steel fibers.

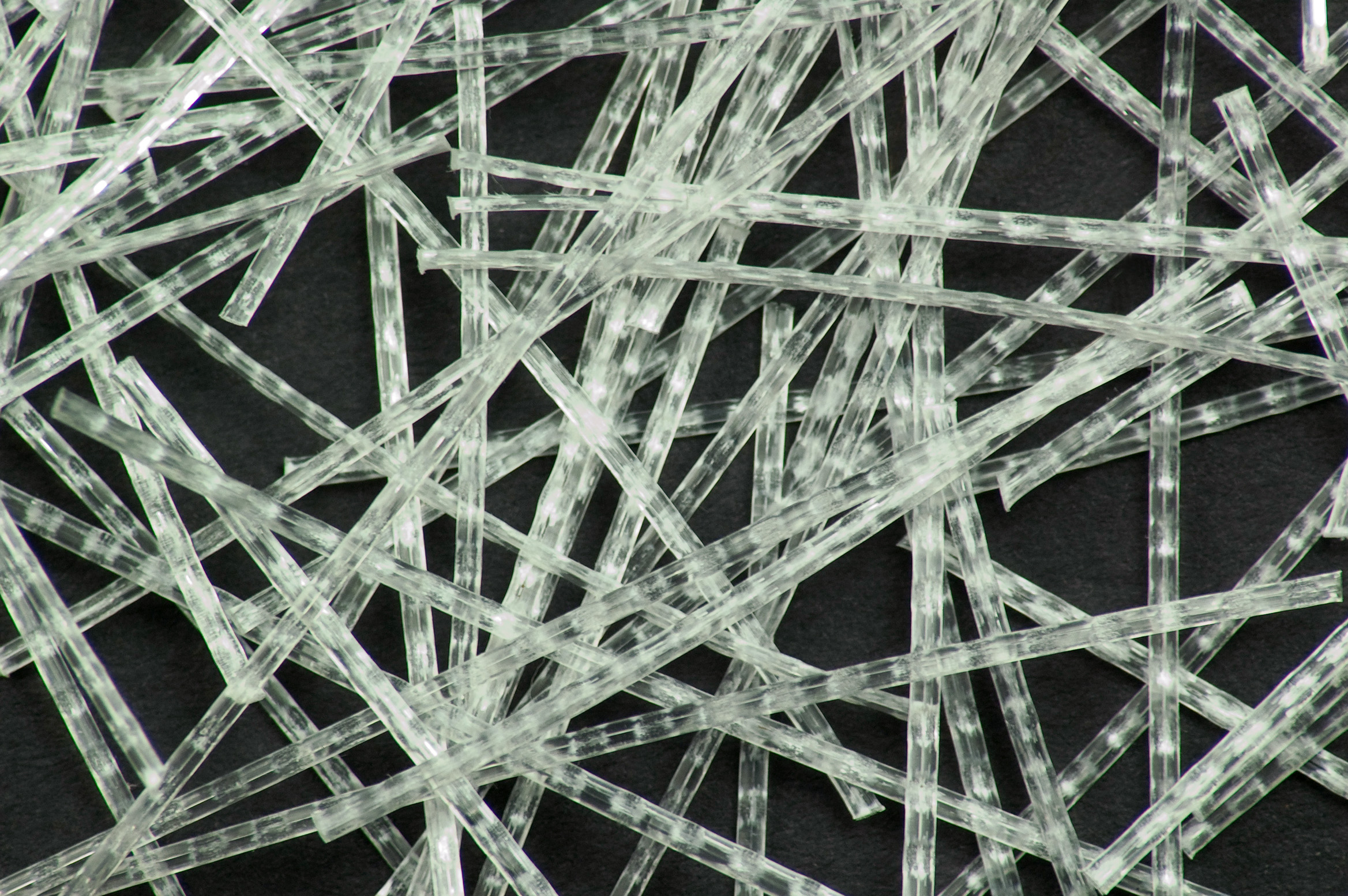

Made from a unique polymer blend, STRUX® 90/40 synthetic macro fibers are patented, high tenacity synthetic monofilaments, designed to replace steel fibers, welded wire mesh, light rebar and other secondary reinforcement in concrete slab-on-ground applications.

Unlike traditional "micro" fiber reinforcement, STRUX® 90/40 is specifically engineered to provide high, post crack-control performance in these applications. STRUX® 90/40 has been shown to reliably achieve average residual strength values in excess of 150 psi that can easily be batched and finished in the field and is easier and safer to use than these other types of secondary reinforcement.

Chuck Fogerson, Project Manager stated, “The concrete consistency with STRUX® synthetic structural fibers was better than with steel fibers,” referring to episodes of clumping and balling when steel fibers had been used in the past. And, while it may be a side benefit, a spokesperson for Imperial Concrete, the concrete contractor noted, “During the finishing process, the wear and tear of steel blades in the finishing machine was drastically less than when steel fibers were used.”

The end result was a smooth, slick finish with uniform distribution of STRUX® 90/40, produced in a quick and efficient manner. In addition, the handling and placement of STRUX® is much safer for workers than steel fibers and welded wire mesh.

Blue360sm Product Performance Advantage.

Because every project, large or small, deserves the best level of protection.

ca.gcpat.com | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

This document is only current as of the last updated date stated below and is valid only for use in the Canada. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://ca.gcpat.com/en/about/project-profiles/strux-renforce-le-plancher-pour-une-construction-de-qualit-sup-rieure